Pre-owned shoe making and Used footwear processing machines In India

Footwear manufacturing in India thrives on innovation and technology, and at the forefront of this evolution is Vatsn Tecnic, a trusted trader dealing in secondhand and old pre-owned shoe-making and footwear-processing machines. Let’s delve into the fascinating world of used footwear processing machines, the diverse landscape of Indian footwear, machinery utilized in various footwear production, and the market valuation associated with this industry.

Types of Footwear in India

India boasts a rich diversity of footwear that caters to diverse needs and preferences:

- Traditional Footwear: Ethnic varieties like Kolhapuris, juttis, and mojaris represent India’s rich cultural heritage.

- Casual Footwear: Sneakers, sandals, and flip-flops dominate the casual footwear segment.

- Formal Shoes: Leather shoes, loafers, and elevated heels meet legal attire requirements.

- Sports Footwear: Catering to the active lifestyle, sports shoes, and specialized athletic footwear are in high demand.

Machinery Used for Different Types of Footwear

Footwear manufacturing involves a spectrum of machinery tailored to specific needs:

- Sole Cutting Machines: Utilized for cutting soles of different sizes and shapes.

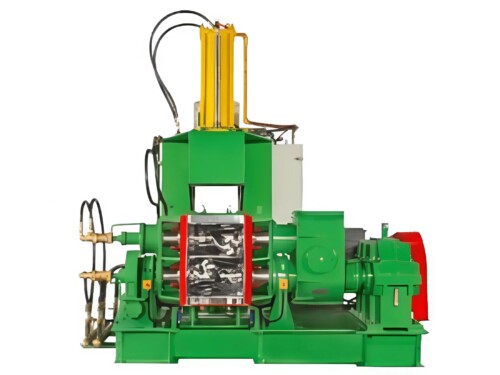

- Moulding Machines: Essential for shaping and molding shoe components.

- Sewing Machines: Used for stitching uppers and assembling footwear.

- Lasting Machines: Vital for stretching and shaping shoe uppers over the shoe lasts.

- Finishing Machines: For polishing, buffing, and adding final touches to footwear.

Footwear Manufacturing Process Overview

The process of making footwear involves multiple stages, each requiring precision and specialized machinery:

- Designing and Pattern Making: Design creation and pattern development are initial stages.

- Material Cutting: Leather, rubber, or other materials are cut per the design requirements.

- Stitching and Assembling: Uppers, insoles, and soles are stitched and assembled using specialized machines.

- Lasting and Bottoming: The upper part is stretched and molded onto the last and then the sole.

- Finishing Touches: We conduct polishing, coloring, and quality checks before packaging.

Benefits of Acquiring Used Footwear-Making Machinery

Benefits of Acquiring Used Footwear-Making Machinery

Investing in pre-owned machinery for footwear production presents several advantages:

- Cost Efficiency: Used machinery reduces initial investment costs. This makes it viable for startups and small-scale manufacturers.

- Quick Setup: The availability of machinery expedites the setup process, enabling faster production commencement.

- Technology Access: Access to high-quality machinery at reduced costs allows manufacturers to leverage advanced technology.

Market Valuation and Opportunities

The Indian footwear market showcases immense potential, with an estimated valuation. The demand for diverse footwear options and the emergence of e-commerce and retail expansion fuels growth in this sector. By offering used footwear-making machinery, Vatsn Tecnic is pivotal in catering to this burgeoning market, aiding entrepreneurs and established manufacturers.

Conclusion

Vatsn Tecnic’s commitment to providing secondhand and old pre-owned shoe-making and footwear-processing machinery echoes the evolving landscape of the footwear industry in India. With an expansive array of machinery suitable for crafting various types of footwear, Vatsn Tecnic facilitates accessibility and affordability in this dynamic market.

Footwear-making machinery is a cornerstone for innovation and growth. It combines technology, affordability, and market opportunities. Vatsn Tecnic is at the forefront of ushering in India’s new era of footwear manufacturing.

Compression Molding

Compression Molding

Benefits of Acquiring Used Footwear-Making Machinery

Benefits of Acquiring Used Footwear-Making Machinery