Old Rubber Sheet Rotocure Machine Supplier in Delhi

Old Rubber Sheet Rotocure Machine Supplier in Delhi – at Best Price

Rubber manufacturing requires precision, especially during the curing stage. One key machine used in the process is the rotocure machine for rubber sheets. Many manufacturers prefer old or pre-owned Rotocure presses due to cost and availability. If you are in Delhi and planning to buy or set up an old rubber sheet rotocure machine, this guide will walk you through the major benefits, government support, top industrial areas, and the best supplier options.

Major Benefits of Setting Up an Old Rubber Sheet Rotocure Machine

Installing an old rubber rotary curing press offers several operational and economic advantages. Here’s why this machine remains essential for rubber sheet manufacturing:

Cost-effective startup: Old machines are cheaper and reduce initial investment.

Proven durability: Rotocure machines last long with proper maintenance.

Continuous production: Offers a non-stop curing process, boosting productivity.

Consistent sheet quality: Ensures uniform thickness and finish.

Compact design: Requires less space than traditional press machines.

Ease of operation: Simple mechanism allows quick training for operators.

Energy efficiency: Older models with proper servicing consume moderate power.

What Is Rubber Curing and How Does It Work?

Curing is a chemical process that uses heat and pressure to improve the strength of rubber, stabilizing it as well as increasing elasticity and durability to become stable. The steps involved in curing rubber are called vulcanization, which is where either sulfur or other agents come into contact with the rubber compound to create a reaction or bond.

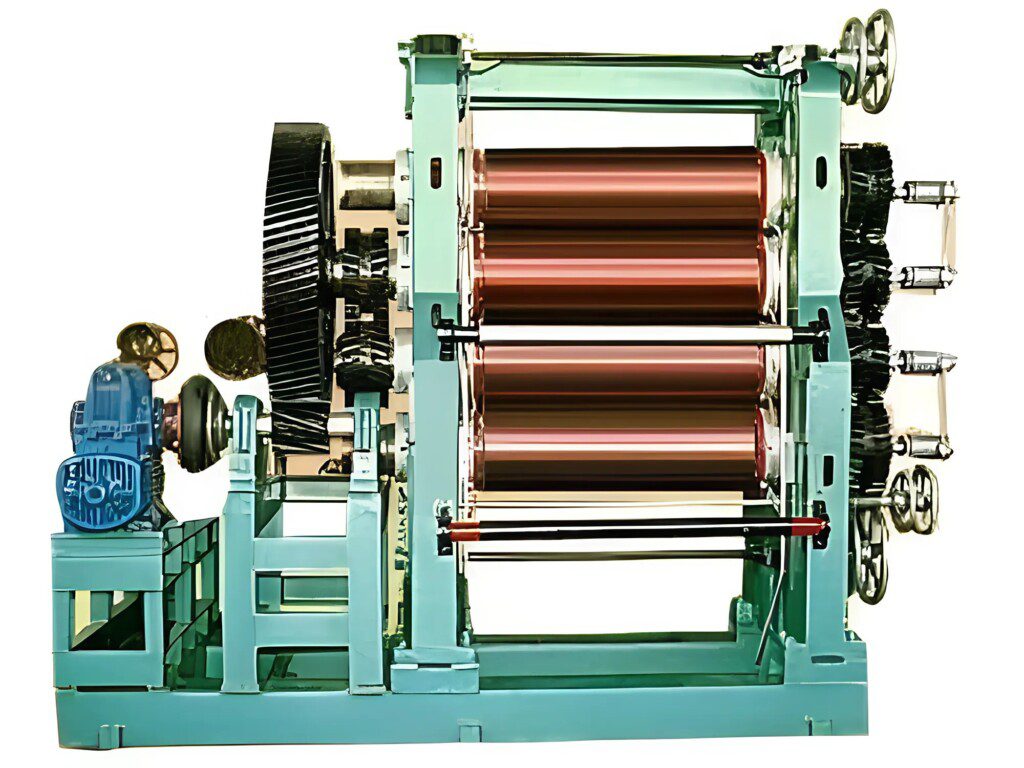

Understanding the Rotocure Process for Rubber Sheets

The Rotocure process uses a rotating heated drum and continuous pressure. The uncured rubber sheet passes between a rubber conveyor and heated drum, where it gets cured uniformly. This method is perfect for long sheet runs and ensures consistent rubber sheet vulcanization.

Can You Get Government Subsidies for Rubber Sheet Rotocure Machines in Delhi?

Yes, Delhi-based businesses can access various government schemes and subsidies to support machine setup:

- MSME Registration Benefits: Small and medium units get a subsidy on machinery costs.

- Startup India Program: New enterprises may apply for grants or subsidized loans.

- Capital Subsidy Scheme: Machinery loans come with reduced interest rates.

- Delhi Industrial Policy 2022: Provides assistance in establishing a plant, training the workforce, and upgrading technology.

- Technology Upgradation Scheme (CLCSS): Up to 15% of the costs incurred in plant & machinery.

Tip: Always register your unit under the Udyam/MSME portal to avail yourself of benefits from incentives.

Where to Set Up Hydraulic Rubber Sheet Curing Machines in Delhi

Delhi offers several ideal industrial areas to install a hydraulic rubber rotary curing press or Rotocure machine:

1. Bawana Industrial Area

- Hub for rubber and plastic manufacturers.

- Easy availability of labor and logistics.

2. Narela Industrial Estate

- Well-planned and developed zone.

- Good infrastructure and road connectivity.

3. Okhla Industrial Area

- Preferred for small- and medium-scale rubber factories.

- Located near major commercial centers.

4. Mundka and Tikri Kalan Zones

- Popular for heavy rubber machinery units.

- Low land rates and better electricity supply.

Pro Tip: Always check zoning regulations before setting up in any industrial area.

Why VatsnTecnic Is the Right Choice for Buying or Selling Old Rotocure Rubber Press

VatsnTecnic is a respected provider of new and used Rotocure Machines in Delhi and all over India. Here are several reasons to consider them:

- Variety of inventory: Many configurations of used and refurbished Rotocure machines.

- Servicing & repairs: Each machine is inspected and repaired by trained technicians before shipping.

- Willing partners and suppliers: Long standing relationships with leading rubber makers in the industry.

- Competitive pricing: Affordable rates for all buyers and sellers.

- Industry experts: Support for machine installation, operation, and upgrades.

- Shipping anywhere in India: Major industrial cities like Mumbai, Chennai, Bangalore and so on.

VatsnTecnic also sells other pre-owned rubber machinery like Banbury Mixers, Hydraulic Presses, Extruders, and Calendering Lines.

Conclusion

Setting up an old Rubber Sheet Rotocure Machine in Delhi is a smart and economical decision. It supports consistent rubber sheet production and aligns with government subsidies aimed at MSMEs. Choose an approved industrial area for smoother operations and better access to labor and logistics. When buying or selling used machines, trust VatsnTecnic, a dependable name known for delivering value, service, and reliability in the rubber machinery sector.

FAQs

Q1. What is the life span of a used Rotocure machine?

A well-maintained Rotocure machine can last over 15–20 years with regular servicing.

Q2. Can old rubber curing machines match the quality of new ones?

Yes, if reconditioned properly, old machines can deliver high-quality results at lower costs.

Q3. Is technical support available after buying an old Rotocure?

VatsnTecnic and similar suppliers provide installation and AMC (Annual Maintenance Contract) services.

Q4. Do industrial areas in Delhi allow setting up heavy rubber machinery?

Yes, zones like Bawana, Narela, and Mundka are approved for rubber and heavy manufacturing.

For More Information Visit Here

Compression Molding

Compression Molding