Hydraulic Rubber Dispersion Kneader Supplier in Nagaland

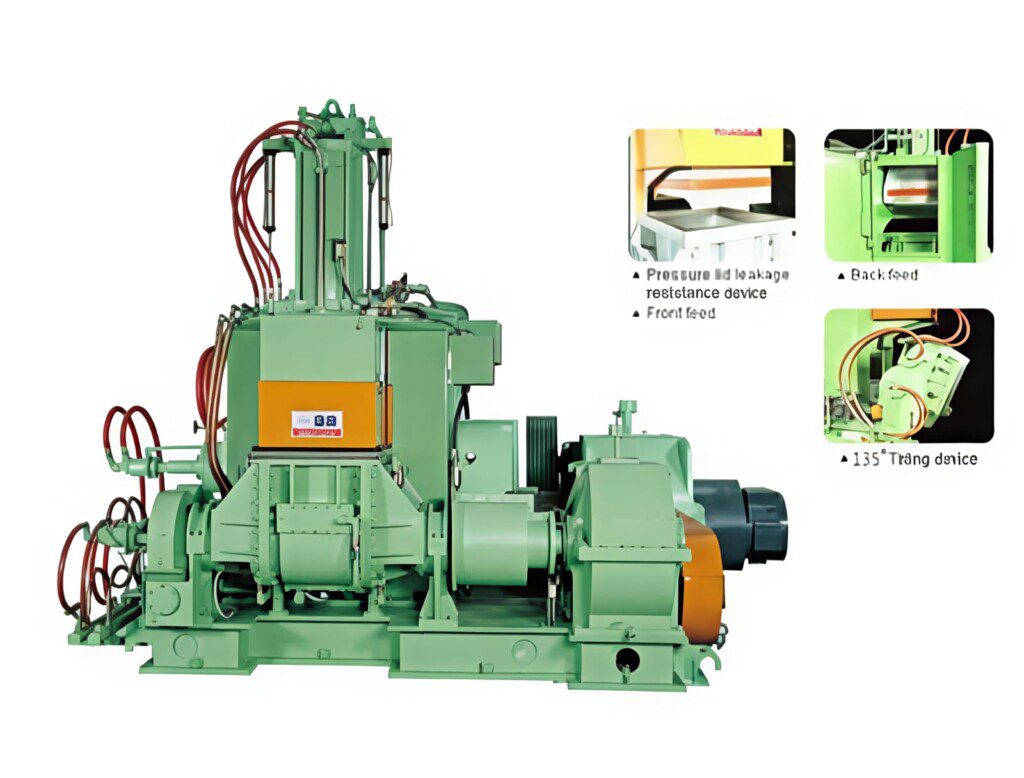

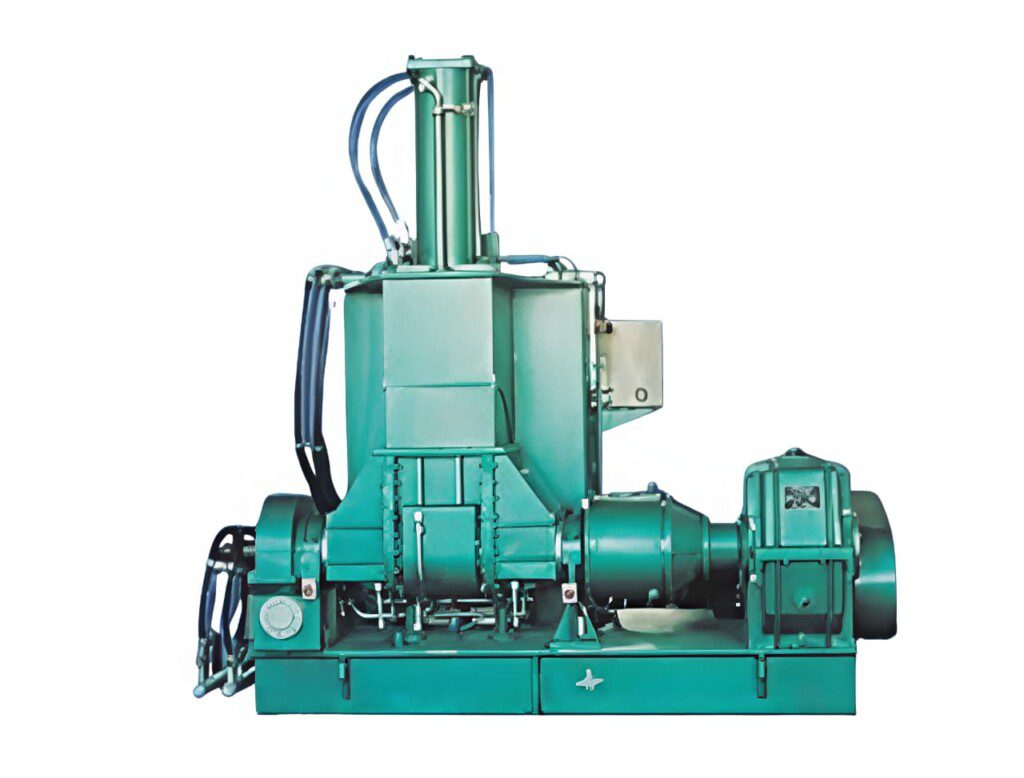

High-Performance Rubber Dispersion Kneader Supplier in Nagaland for Industrial System Production Line

A high-performance rubber dispersion kneader plays an essential role in modern rubber manufacturing operations.

Moreover, Nagaland is gaining recognition as a growing hub for industrial equipment supply.

Therefore, manufacturers now focus on reliable machinery partners for consistent operational results.

In addition, efficient kneading systems improve mixing quality throughout the production process.

As a result, industries achieve stable output and reduced material loss.

Furthermore, dependable suppliers support structured production system development.

Consequently, businesses experience smoother workflows across the industrial system production line.

Moreover, advanced kneading technology supports scalable machine making processes.

Therefore, Nagaland continues attracting attention from rubber processing industries nationwide.

Benefits of a Reliable Production Process for Rubber Manufacturing Equipment

A reliable production process strengthens overall industrial manufacturing efficiency.

Moreover, structured operations help equipment production units meet market demand.

Key advantages include:

Moreover, consistent processes improve product uniformity.

Therefore, industrial manufacturing steps face fewer interruptions.

In addition, production system development becomes more predictable.

As a result, machine making processes operate efficiently.

Furthermore, equipment production units meet quality standards.

Consequently, industrial production lines scale smoothly.

Government Scheme for Setting Up an Industrial Machinery Supply Business

Government initiatives support structured industrial development across multiple regions.

Moreover, policy frameworks encourage investment in manufacturing equipment supply.

Major support initiatives include:

Moreover, MSME schemes assist machinery suppliers financially.

Therefore, capital subsidies reduce initial investment pressure.

In addition, infrastructure programs strengthen industrial operations.

As a result, logistics support improves supply chain efficiency.

Furthermore, skill programs enhance workforce capability.

Major Industrial Areas for Setting Up Manufacturing Equipment Units

Strategic industrial locations help businesses expand production capacity.

Moreover, Nagaland offers developing infrastructure for industrial growth.

Key industrial zones include:

Moreover, Dimapur Industrial Growth Centre supports manufacturing units.

Therefore, Niuland Industrial Estate enables large-scale operations.

In addition, Kohima Industrial Area aids system development.

As a result, Mokokchung Industrial Zone attracts investments.

Furthermore, Tuli Industrial Area strengthens regional supply chains.

How Industrial Rubber Systems Are Made | Step-by-Step Manufacturing Process

Industrial rubber systems follow structured industrial manufacturing steps.

Moreover, each stage supports effective production system development.

Design and Planning Stage

First, engineers plan the production process using operational requirements.

Moreover, layouts align with the industrial system production line.

Material Selection Process

Next, teams select suitable materials for equipment durability.

Therefore, performance improves across production units.

Component Fabrication Stage

Then, technicians fabricate components under controlled conditions.

In addition, precision enhances system reliability.

Assembly and Integration

Afterward, components integrate into the production line.

As a result, operational alignment improves.

Testing and Calibration

Subsequently, teams test machinery performance thoroughly.

Moreover, calibration ensures consistent operational output.

Final Deployment

Finally, systems deploy into active manufacturing environments.

Therefore, production system development reaches completion.

Why Choose VatsnTecnic for Industrial Machine Manufacturing

VatsnTecnic delivers reliable industrial machinery solutions with technical expertise.

Moreover, the company focuses on efficient production process execution.

Key strengths include:

Moreover, expert engineering supports system development.

Therefore, technical support ensures uninterrupted operations.

In addition, reliable machines strengthen production efficiency.

As a result, manufacturing processes achieve higher accuracy.

Furthermore, after-sales service ensures long-term reliability.

Delhi Government Schemes Supporting Industrial Manufacturing Growth

Delhi policies encourage growth in industrial manufacturing activities.

Moreover, schemes assist equipment production units and suppliers.

Key initiatives include:

Moreover, startup incentives support machinery businesses.

Therefore, capital subsidies improve production capacity.

In addition, infrastructure schemes strengthen industrial systems.

As a result, technology grants enhance operational efficiency.

Furthermore, export support expands market reach.

Moreover, selecting the right machinery supplier ensures consistent operational performance.

Therefore, strategic planning supports sustainable industrial growth.

In addition, structured production system development improves scalability.

As a result, manufacturers gain long-term competitive advantages.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

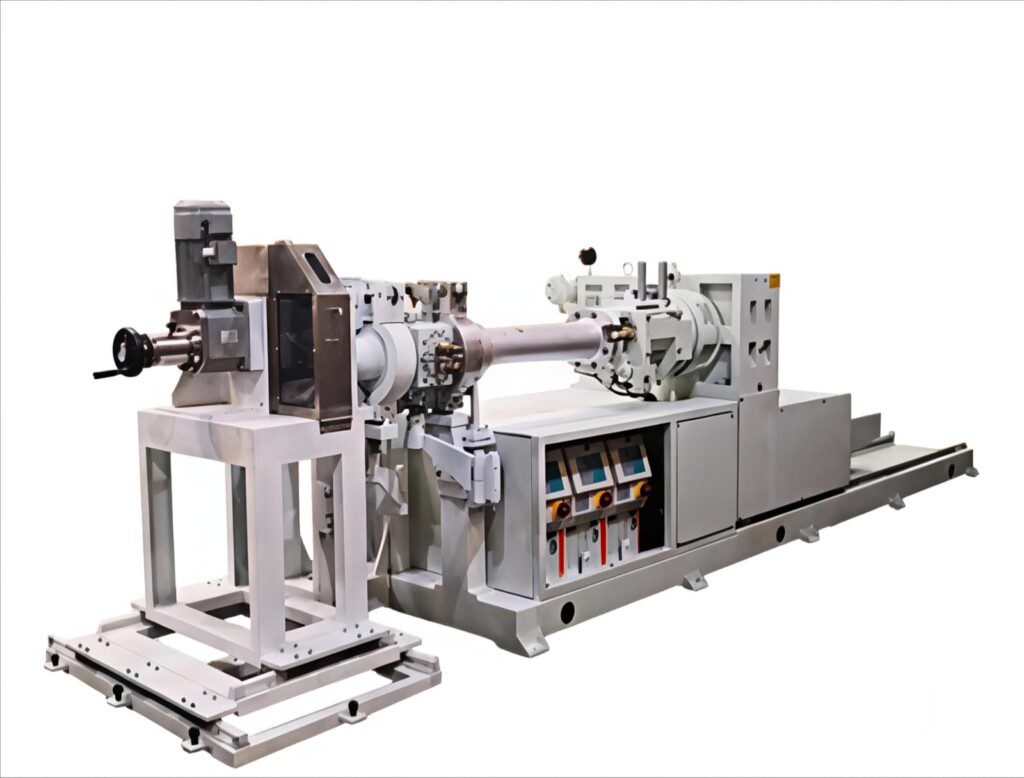

Compression Molding

Compression Molding