Cold Feed Rubber Extruder Line – Himachal Pradesh

Cold Feed Rubber Extruder Line – Himachal Pradesh

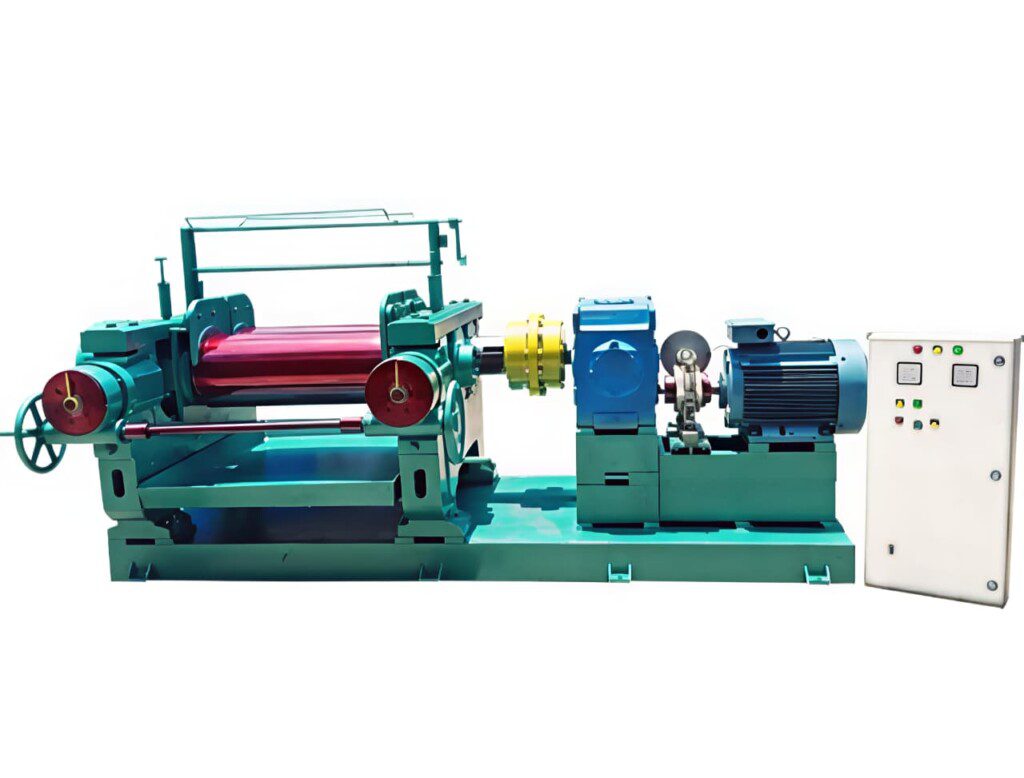

A Cold Feed Rubber Extruder Line in Himachal Pradesh streamlines the rubber compounding production process efficiently. Moreover, it supports precise industrial manufacturing steps for high-quality output. In addition, modern production system development reduces energy consumption and enhances consistency. Therefore, machine making process follows strict engineering standards for reliability. As a result, equipment production units integrate seamlessly into the industrial system production line. Moreover, understanding the crocs slipper machine in Surat working principle helps operators manage extrusion parameters effectively. In addition, advanced industrial manufacturing steps ensure minimal downtime and consistent rubber quality.

Benefits of a Reliable Production Process in Himachal Pradesh | Industrial Manufacturing Steps

Moreover, production process ensures consistent rubber extrusion quality

Therefore, industrial manufacturing steps reduce material waste

In addition, production system development improves throughput efficiency

As a result, machine making process lowers maintenance frequency

Moreover, equipment production units deliver uniform output

Therefore, industrial system production line enhances operational reliability

Government Scheme for Setting Up a Trusted Supplier | Production System Development

Moreover, MSME schemes support advanced production system development

Therefore, capital investment incentives reduce financial pressure

In addition, technology upgrade support improves machine making process

As a result, equipment production units expand faster

Moreover, industrial development support strengthens industrial system production line

Major Industrial Areas for Setting Up Cold Feed Rubber Extruder | Industrial System Production Line

Moreover, Baddi Industrial Area

Therefore, Nalagarh Industrial Cluster

In addition, Parwanoo Manufacturing Zone

As a result, Solan Industrial Estate

Moreover, Hamirpur Industrial Corridor

How Industrial Systems Are Made | Cold Feed Rubber Extruder Step-by-Step Manufacturing Process Using Production Process

Industrial systems follow a structured production process for high reliability. Moreover, planning begins with detailed industrial manufacturing steps and equipment layout. Therefore, production system development includes thermal analysis, material flow, and quality parameters. In addition, the machine making process ensures precise alignment of all components. As a result, equipment production units maintain continuous output across the industrial system production line. Moreover, operators trained in crocs slipper machine in Surat working principle can adjust extruder settings efficiently. In addition, testing validates the entire industrial manufacturing steps and production system development before dispatch.

Why Choose VatsnTecnic? | Industrial Manufacturing Steps & Machine Making Process

VatsnTecnic provides reliable industrial manufacturing steps and production system development for rubber extrusion machinery. Moreover, expert teams manage the machine making process with precision. Therefore, equipment production units maintain high uptime and consistent output. In addition, clients benefit from strong technical support and seamless integration into industrial system production lines. As a result, crocs slipper machine in Surat working principle can be applied effectively in Himachal operations. Moreover, VatsnTecnic’s production process ensures durability and long-term performance for all industrial manufacturing steps.

Himachal Pradesh Government Schemes | Equipment Production Units & Production Process

Moreover, MSME capital subsidy schemes

Therefore, interest reimbursement for equipment production units

In addition, technology upgradation incentives

As a result, skill development support for production process

Moreover, export promotion schemes for industrial system production line

Cold Feed Rubber Extruder Lines in Himachal Pradesh optimize rubber compounding production process. Moreover, structured industrial manufacturing steps ensure uniform material flow. Therefore, production system development enhances throughput and reduces waste. In addition, operators can use crocs slipper machine in Surat working principle to improve extrusion accuracy. As a result, equipment production units achieve stable output across the industrial system production line. Moreover, machine making process is designed for minimal maintenance and maximum reliability. In addition, industrial manufacturing steps support large-scale rubber extrusion operations with efficiency.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For More Information Visit Here

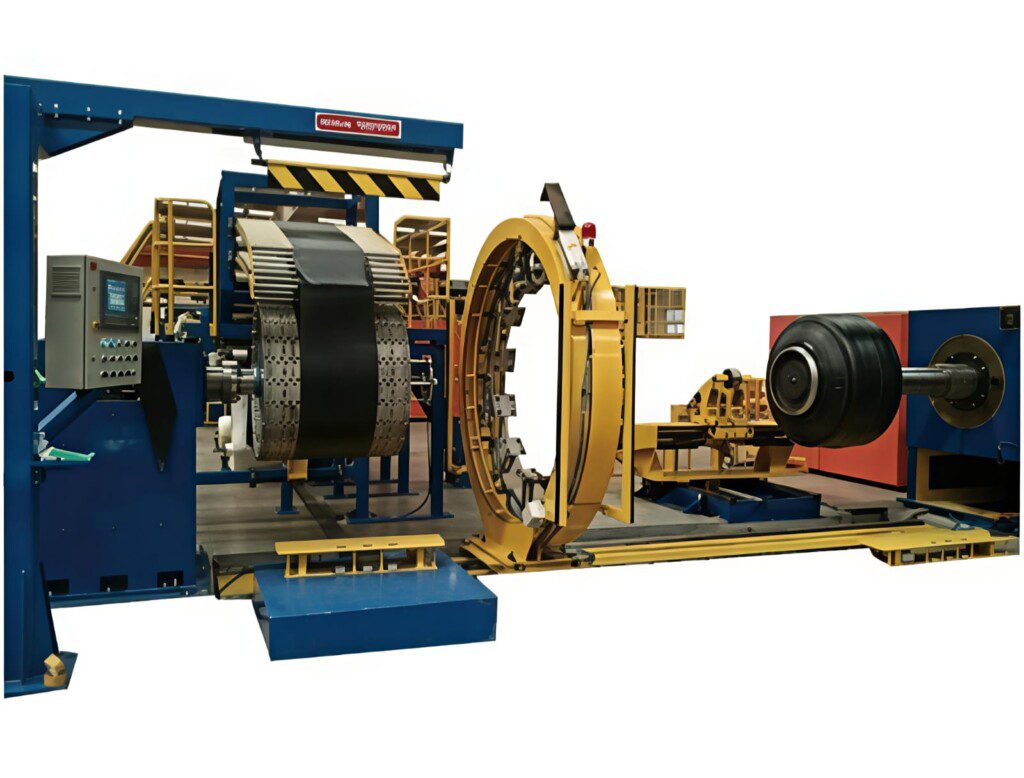

Compression Molding

Compression Molding