PLASTIC PROCESSING MACHINERY

20

May

Best Thermoforming Machine Service Providers in GujaratGujarat is emerging as a hub for thermoforming machine services. From sheet th...

08

May

Reliable Plastic Blow Molding Machine Exporter in Uttarakhand

Reliable Plastic Blow Molding Machine Exporter in UttarakhandUttarakhand is fast emerging as a manufacturing center. Of the emerging ...

01

Apr

All-Electric Injection Molding Machines in Mumbai

All-Electric Injection Molding Machines in Mumbai: A Smart Investment for Manufacturers

Why Invest in a Used All-Electric Injection Mo...

26

Mar

Automatic Plastic Processing Machines in Delhi

Automatic Plastic Processing Machines in Delhi

The requirement for plastic processing machines is surging tremendously in Delhi with t...

16

Jan

Hot Feed Rubber Extruder Machine in Himachal Pradesh

Hot Feed Rubber Extruder Machine in Himachal Pradesh

Himachal Pradesh has become an ever more attractive destination for different ind...

26

Dec

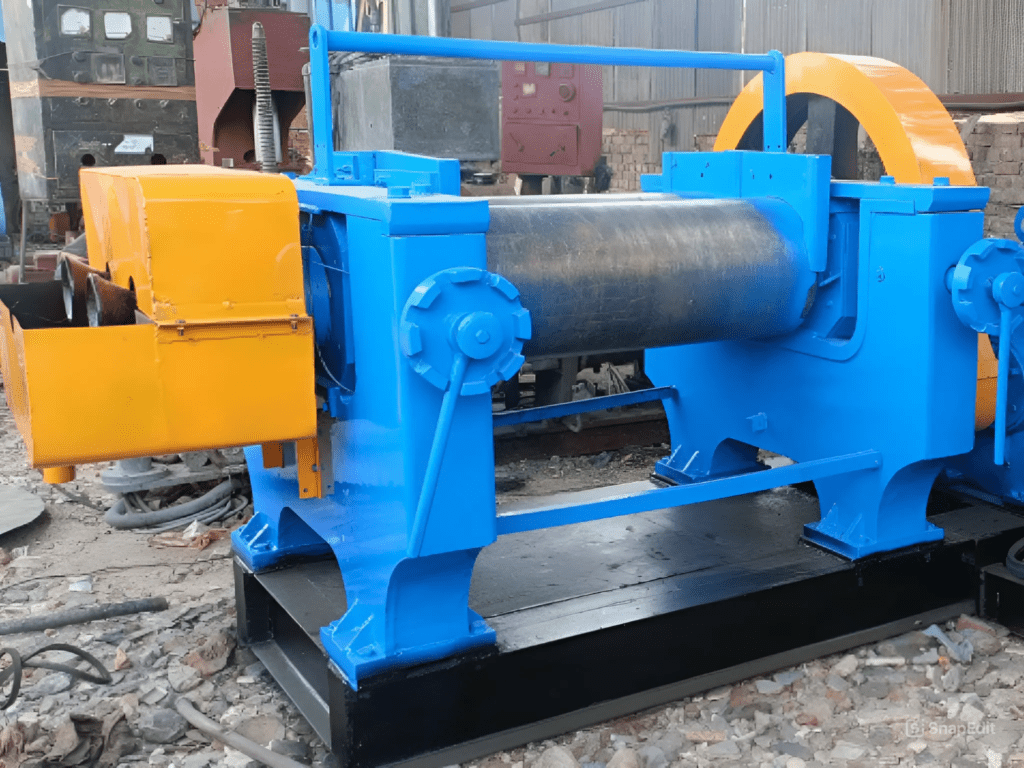

Rubber Mixing Mill Importer in Maharashtra

Maharashtra is one of India’s leading industrial hubs, offering immense business opportunities in the rubber industry. With its strateg...

20

Dec

Rubber Refiner Mill Supplier in Jharkhand

With its abundant natural resources and strategic location, Jharkhand is emerging as a hub for various industries, including the rubber...

15

Oct

Top Plastic Processing Machinery for Efficient Manufacturing

Today, processing machinery is needed to help businesses tackle the hectic demands of the competitive manufacturing environment. The ma...

26

Feb

Good Quality Used Rubber Oil Seal Manufacturing Machine

In the realm of manufacturing, precision and reliability are paramount. This is especially true in industries where parts face harsh co...

Compression Molding

Compression Molding