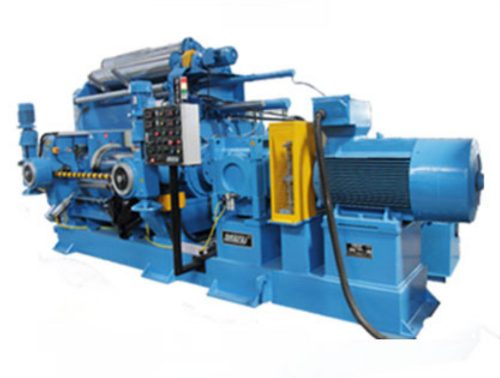

Automatic Rubber Compression Press

Automatic Rubber Compression Molding Press: Industrial Manufacturing Solution

The Automatic Rubber Compression Molding Press plays a key role in modern rubber manufacturing. Its efficiency improves production processes significantly. Moreover, manufacturers can optimize output while maintaining consistent quality. This equipment supports industrial system production lines. Therefore, businesses investing in advanced machinery experience smoother industrial manufacturing steps. In addition, the machine making process becomes more streamlined with automation. As a result, equipment production units achieve higher productivity with reduced labor dependency.

Benefits of a Reliable Rubber Manufacturing Production Process in Maharashtra

A robust production process ensures smooth industrial system production line performance. Key advantages include:

Improves efficiency in equipment production units and reduces operational delays.

Enhances quality control during industrial manufacturing steps.

Reduces material wastage and improves cost-effectiveness.

Strengthens production system development with advanced monitoring systems.

Supports faster turnaround in industrial system production lines.

Encourages scalability for machine making process in large-scale units.

Promotes sustainable production practices within industrial manufacturing steps.

Moreover, companies in Maharashtra benefit from reduced downtime. Therefore, investing in a reliable production process improves long-term growth.

Government Schemes for Setting Up a Trusted Rubber Equipment Supplier

The Indian government supports production system development in industrial units. Key initiatives include:

Financial support for new equipment production units.

Subsidies for installing industrial system production lines.

Grants to upgrade machine making process technology.

Training programs for staff in industrial manufacturing steps.

Tax incentives for trusted rubber machinery suppliers.

As a result, these schemes boost industrial system production line growth. Moreover, small and medium manufacturers can adopt efficient production processes.

Major Industrial Areas for Rubber Machinery Setup

Selecting the right location improves industrial system production line efficiency. Top industrial zones include:

Pune Industrial Area – ideal for advanced machine making process facilities.

Nashik Industrial Hub – supports large-scale production system development.

Aurangabad Industrial Zone – equipped for modern industrial manufacturing steps.

Mumbai-Pune Corridor – suitable for equipment production units expansion.

Nagpur Industrial Park – perfect for reliable rubber machinery setup.

Moreover, these regions provide strong logistics support. Therefore, businesses enjoy seamless industrial system production line operations.

How Industrial Systems for Rubber Molding Are Made | Step-by-Step Production Process

The industrial system production line for rubber molding follows structured steps:

Step 1: Material Selection

Manufacturers choose high-quality rubber and additives. Moreover, selecting proper materials ensures durability.

Step 2: Preheating and Mixing

Raw materials undergo preheating and uniform mixing. In addition, this improves machine making process efficiency.

Step 3: Mold Preparation

Molds are cleaned and treated for precise shaping. Therefore, production system development remains consistent.

Step 4: Compression Molding

Rubber is placed in the mold and compressed under high pressure. As a result, equipment production units achieve uniform thickness.

Step 5: Curing Process

The material cures under controlled temperature and pressure. Moreover, this step ensures durability in industrial manufacturing steps.

Step 6: Demolding and Inspection

Finished products are removed carefully and inspected. In addition, quality control is maintained across the production system development line.

Step 7: Packaging and Dispatch

Products are packed and sent for delivery. Therefore, equipment production units maintain reliability in industrial system production lines.

Why Choose VatsnTecnic for Rubber Molding Industrial Machine Manufacturing

VatsnTecnic offers advanced industrial system production line solutions. Benefits include:

High reliability ensures smooth production system development in industrial manufacturing steps.

Technical support optimizes the machine making process efficiently.

Advanced equipment production units deliver consistent performance.

Customized solutions suit varying industrial system production line requirements.

Compliance with Delhi government schemes ensures regulatory support and incentives.

Moreover, VatsnTecnic integrates cutting-edge automation in equipment production units. In addition, production process efficiency improves significantly. Therefore, businesses can expand industrial system production lines confidently.

Delhi Government Schemes for Industrial Machine Manufacturers

Financial incentives for trusted equipment production units.

Grants for upgrading industrial system production lines.

Subsidies for adopting automated machine making process technology.

Skill development programs for industrial manufacturing steps staff.

Tax benefits to encourage production system development investments.

As a result, Delhi-based industrial units achieve cost-effective growth. Moreover, these schemes strengthen industrial system production line efficiency.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For More Information Visit Here

https://www.indiamart.com/vatsntecnic/profile.html

Compression Molding

Compression Molding