Single Screw Hot Feed Rubber Extruder Explained

Single Screw Hot Feed Rubber Extruder Explained

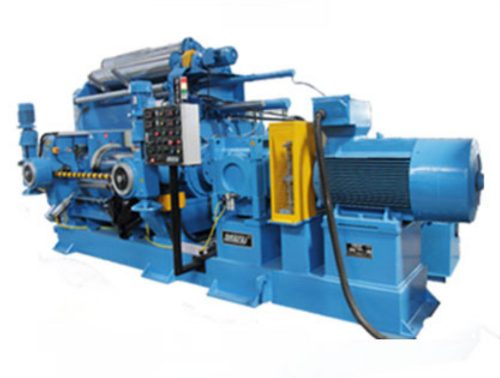

A single screw hot feed rubber extruder plays a critical role in rubber processing industries. Moreover, this machine supports a continuous production process for shaping rubber compounds. Therefore, manufacturers rely on it for stable industrial manufacturing steps. In addition, proper production system development improves extrusion consistency. As a result, equipment production units deliver uniform output across an industrial system production line.

Key Functions of Single Screw Hot Feed Rubber Extruder

Moreover, feeds preheated rubber efficiently

Therefore, supports continuous production process

In addition, stabilizes industrial manufacturing steps

As a result, improves surface finish quality

Moreover, reduces manual handling effort

Working Principle of Hot Feed Rubber Extruder

The hot feed rubber extruder operates using a rotating screw inside a heated barrel. Moreover, the screw pushes softened rubber forward during the production process. Therefore, pressure builds gradually along industrial manufacturing steps. In addition, controlled heating supports production system development. As a result, the machine-making process ensures uniform extrusion through the die.

Core Components Involved in Machine-Making Process

Moreover, hardened steel screw ensures durability

Therefore, heated barrel supports rubber plasticity

In addition, gearbox controls industrial manufacturing steps

As a result, die head shapes rubber accurately

Moreover, motor drives the industrial system production line

Advantages of Using Single Screw Hot Feed Rubber Extruder

A single screw hot feed rubber extruder improves overall manufacturing efficiency. Moreover, it simplifies the production process for various rubber profiles. Therefore, operators manage industrial manufacturing steps easily. In addition, optimized production system development reduces energy usage. As a result, equipment production units deliver cost-effective output.

Applications Across Industrial System Production Line

Moreover, used in rubber strip production

Therefore, supports hose and tubing manufacturing

In addition, suitable for tyre component extrusion

As a result, ideal for seals and gaskets

Moreover, adapts well to continuous production process

Role in Modern Production System Development

Modern factories integrate hot feed extruders into advanced production system development. Moreover, automation enhances control over industrial manufacturing steps. Therefore, consistency improves across the industrial system production line. In addition, data monitoring supports machine-making process optimization. As a result, equipment production units achieve predictable performance.

Maintenance Practices for Reliable Production Process

Moreover, regular screw inspection prevents wear

Therefore, barrel cleaning ensures smooth production process

In addition, gearbox lubrication supports industrial manufacturing steps

As a result, downtime reduces significantly

Moreover, scheduled servicing protects equipment production units

Energy Efficiency and Cost Control

Energy efficiency remains essential in rubber extrusion operations. Moreover, hot feed extruders reduce reheating needs during the production process. Therefore, industrial manufacturing steps consume less power. In addition, efficient production system development lowers operational costs. As a result, the industrial system production line becomes more sustainable.

Selection Criteria for Industrial Manufacturing Steps of Single Screw Rubber Extruder

Moreover, consider output capacity requirements

Therefore, match screw design with rubber compound

In addition, evaluate heating control systems

As a result, ensure compatibility with production process

Moreover, assess support for equipment production units

Quality Control in Machine-Making Process of Single Screw Rubber Extruder

Quality control ensures consistent results from a hot feed rubber extruder. Moreover, testing aligns machine-making process standards with industrial manufacturing steps. Therefore, defects reduce during the production process. In addition, monitoring improves production system development outcomes. As a result, equipment production units meet customer specifications.

Safety Considerations in Industrial System Production Line

Moreover, guards protect operators from moving parts

Therefore, temperature controls prevent overheating

In addition, emergency stops enhance production process safety

As a result, industrial manufacturing steps remain secure

Moreover, training improves equipment production units handling

Why Single Screw Hot Feed Rubber Extruders Remain Popular

Single screw hot feed rubber extruders remain widely adopted in rubber factories. Moreover, their simple design supports reliable production process control. Therefore, industrial manufacturing steps stay manageable for operators. In addition, flexible production system development meets diverse requirements. As a result, the industrial system production line maintains consistent output.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For More Information Visit Here

Compression Molding

Compression Molding