Used Rubber Mixing Mill – Chandigarh

Used Rubber Mixing Mill – Chandigarh: Reliable Rubber Processing Solutions

For those looking for an economical and effective method to blend rubber for industrial applications, a pre-owned rubber mixing mill presents a clever option. For workshops and manufacturers in and near Chandigarh, investing in a refurbished mixing mill ensures reliable operation with reduced downtime. This article examines the operational principle, main advantages, considerations for purchasing a pre-owned mill, and how a “Used Rubber Mixing Mill – Chandigarh” can act as a valuable resource for rubber-processing enterprises.

What is a Rubber Blending Mill?

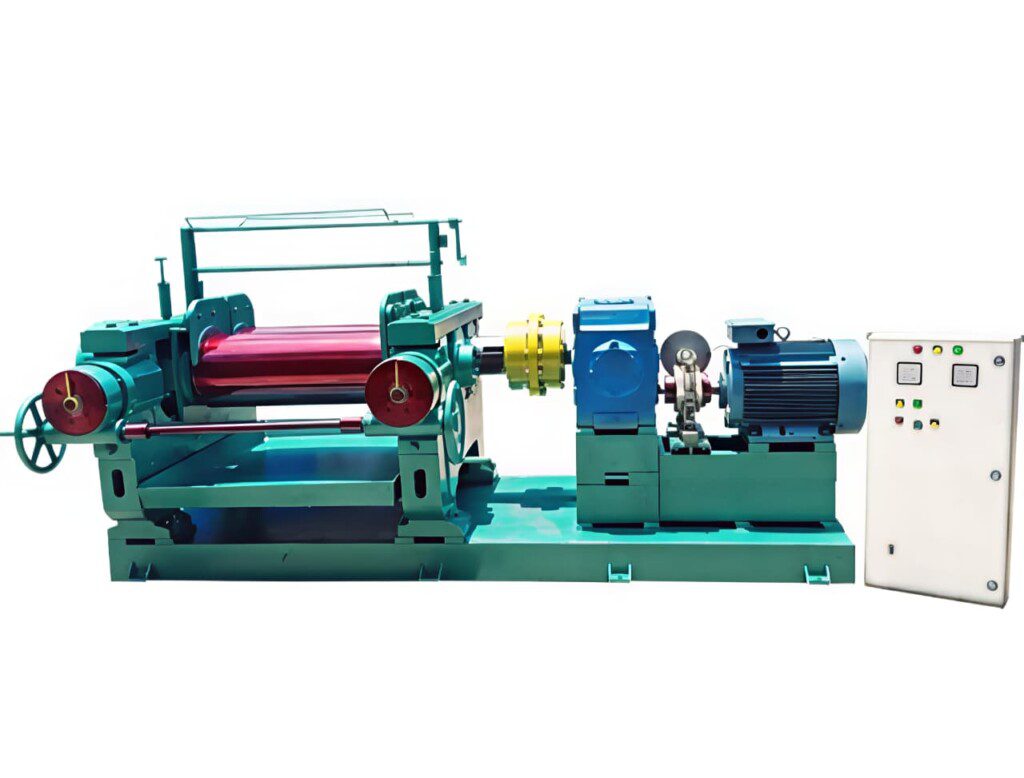

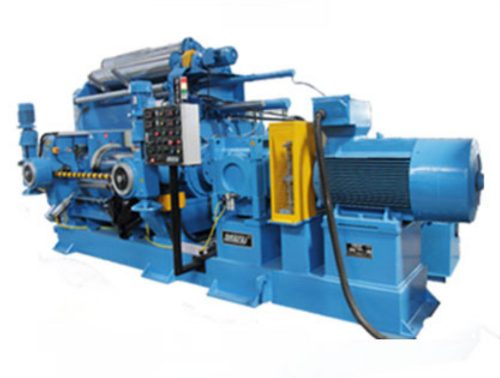

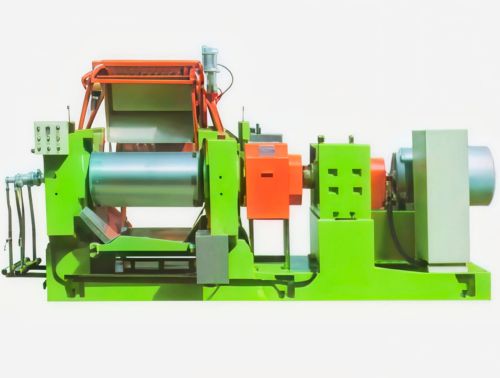

generally A rubber mixing mill — typically a two-roll mill — employs two large, counter-rotating rolls to blend raw rubber with additives, fillers, and various compounding agents. another The rolls turn toward one another, forming a nip point that pulls in rubber and mixes it under significant shear and pressure. This method unravels polymer chains and evenly disperses chemicals across the mixture.

This mill fulfills multiple functions: blending raw rubber, creating sheets, plasticizing mixtures. and getting rubber ready for subsequent processes like extrusion, molding, or calendaring.

A properly refurbished and maintained used mixing mill provides many similar advantages to a new model — frequently at a significantly reduced price, particularly for small and medium-sized rubber-processing facilities

Reasons to Purchase a Pre-Owned Rubber Mixing Mill in Chandigarh

Reconditioned mills offer essential mixing and sheeting capabilities without the significant initial expenses tied to purchasing new machinery. Suppliers throughout India restore two-roll mills to guarantee their dependable performance for uniform rubber compounding.

For companies close to Chandigarh — including tyre repair shops, rubber product producers. small-scale rubbersizing businesses — a second-hand mill lessens initial financial strain while allowing for superior compound preparation.

Consistent Blending and Material Flexibility

Even used mills, when well-maintained, provide consistent mixing due to the rolls’ shearing action. This guarantees uniform distribution of fillers, plasticizers, accelerators, and various additives.

Used mills accommodate numerous raw materials — natural rubber, synthetic rubber, blends, recycled rubber. providing manufacturers the versatility to create various rubber compounds.

Fast Prepared for Use After Renovation

Trusted vendors of second-hand mills usually restore and rigorously test equipment prior to shipping. They maintain the drive system, examine and repair rolls, check alignment and nip adjustments, and confirm that safety features are functional. This prepares the mill for instant industrial use upon delivery — a significant benefit for companies aiming to minimize downtime or quickly increase capacity.

Resource Efficiency & Sustainable Utilization

Utilizing refurbished equipment demonstrates a sustainable approach — prolonging machinery lifespan, minimizing industrial waste, and optimizing resource use. For rubber-processing companies focused on environmental and economic efficiency, a second-hand mixing mill provides a practical, responsible option.

Important Attributes & Specifications to Consider Before Purchasing Used

When evaluating a second-hand rubber mixing mill, particularly around Chandigarh or other industrial centers in India, concentrate on these essential factors to guarantee lasting reliability and efficiency:

Material and Condition of Roll

Premium two-roll mills utilize chilled cast iron or alloy steel rollers featuring hardened surfaces and exceptional wear resistance. Rolls must possess a consistent surface finish, be free of cracks, and maintain proper concentricity to prevent uneven mixing or early failure.

If the rolls exhibit significant wear, pitting, or an uneven surface — steer clear of the mill, or confirm re-conditioning prior to usage. When properly refurbished, rolls regain effective shearing action and consistent compound quality.

Propulsion Mechanism and Rotation Velocity/Friction Proportion

Verify the type of drive — mills can function using bull-gear drive, uni-drive, or hydraulic drive systems, based on their model and capacity needs.

The ratio of roll speed to friction is vital for attaining effective mixing. The variation in rolling speeds creates shear that evenly distributes fillers and additives. An appropriate friction ratio guarantees sufficient mixing without causing overheating or harm to the compound.

Nip-Gap Modification and Temperature Regulation

Make sure the mill enables precise and consistent adjustment of nip (the space between rolls). This aids in regulating sheet thickness, blending pressure, and guarantees uniform compound consistency.

If the mill provides temperature control (cooling/heating or roll surface temperature management), examine the system thoroughly — effective temperature regulation avoids scorching or overheating raw rubber during mixing, preserving compound quality.

Overall Mechanical and Structural Soundness

Verify that the frame is sturdy and secure — a properly constructed steel frame, strong welds, and absence of structural cracks guarantee durability and safe functioning.

Examine bearings, gears, and the gearbox — they need to be operational, running smoothly, without loud noises or excessive movement. Well-maintained bearings minimize vibration and guarantee steady roll alignment during use.

Safety Elements & Regulations

Safety is crucial due to the open nip point where the rolls of two-roll mills come together. Verify that the machine is equipped with emergency-stop bars, mechanical barriers or safety interlocks, and that all controls operate properly.

Adequate guarding and operator training are crucial — safety incidents may arise from the pulling force of rolls, and outdated machines lacking safety measures carry greater risk.

Typical Applications and Sectors That Gain from Reused Rubber Mixing Mills

- Tyre & Tube Repair Shops — for creating formulation batches necessary for retreading tyres or fixing tubes. A dependable mill guarantees consistent material for patches, sidewall repairs, or tube production.

- Rubber Products Production — creating hoses, belts, gaskets, seals, conveyor belts, rubber flooring, and industrial parts. The mill facilitates the preparation of custom rubber compounds based on material specifications.

- Footwear & Sole Production — combining rubber materials for shoe soles, heels, and different footwear elements where flexibility and endurance are crucial.

- Recycling Rubber Processing — mills assist in blending reclaimed rubber with new materials or additives, supporting recycling initiatives and creating sustainable rubber products.

Used mills are adaptable to different types and compounds of rubber — whether natural, synthetic, or recycled — which maintains their versatility across various industries.

Advantages & Disadvantages — Key Information to Consider

- Cost efficiency: Reduced upfront expenditure relative to new equipment — perfect for smaller or budget-aware businesses.

- Established mechanical design: Two-roll mills have a long history of industrial application and dependable performance when properly maintained.

- Versatility: Appropriate for various types of raw rubber and compound formulations.

- Rapid setup: Refurbished mills are typically operational immediately upon installation — reducing downtime, particularly during periods of high demand.

Constraints & Potential Issues to Keep in Mind

- Safety risks: The open nip configuration can create significant accident dangers if operators are careless or if safety mechanisms are inadequate.

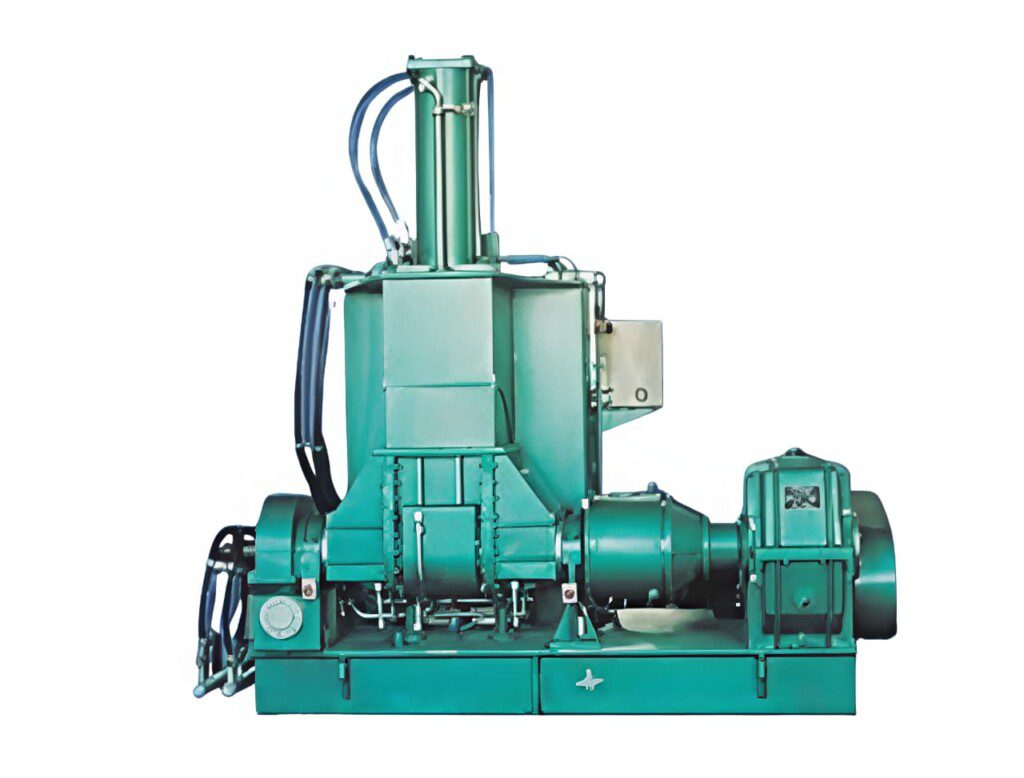

- Limitations of batch processing: Being a batch-oriented machine, its throughput is restricted when compared to continuous or advanced internal mixers; increasing production may become more challenging if there is a rise in demand.

- Risk of deterioration: Pre-owned mills might possess damaged rolls, misaligned structures, or worn-out bearings—such deterioration can result in uneven mixing or early breakdown if not appropriately restored.

- Environmental and cleanliness issues: Due to open mixing, dust or impurities can infiltrate the compound — unsuitable for ultra-clean or sensitive rubber compounds lacking a controlled environment.

Understanding these trade-offs enables buyers to make informed choices, weighing cost against operational requirements, safety, and durability over time.

Actions to Take for a Successful Purchase — Pre-Purchase Checklist for Buyers in Chandigarh

basically Should you choose to purchase a pre-owned rubber mixing mill — particularly in Chandigarh or adjacent industrial areas — consult this checklist to guarantee you obtain a reliable, safe equipment:

- Carefully examine the roll surfaces — ensure there are no cracks, uniform hardness/surface finish, and that concentricity is maintained.

- Conduct a test drive of the machine — verify roll alignment, ensure smooth functioning of the drive system, and check for any excessive vibration or noise.

- Check the nip-adjustment and roll-gap controls — confirm they function accurately and seamlessly.

- Inspect temperature regulation systems (if available) — to ensure water-cooling, heating, or thermostat control functions correctly.

- Verify that safety mechanisms are operational — emergency stop buttons, protective guards, interlock systems, and operator controls should be complete.

Reasons for the Use of Rubber Mixing Mill in Chandigarh’s Industry

Chandigarh and its nearby areas have numerous rubber-processing facilities, ranging from small shops. medium-sized manufacturers that create tyres, hoses, mats, soles, and various rubber products. For these sectors, a second-hand mixing mill provides a practical equilibrium of cost, performance, and adaptability.

By using refurbished two-roll mills, businesses are able to:

- Initiate or grow rubber compounding without significant upfront investment.

- Modify compound formulations as required for various end-products.

- Maintain low maintenance and operating expenses — a more straightforward mechanical design allows for local servicing and access to parts.

- Ensure production flexibility — for smaller quantities, experimental mixtures, or bespoke tasks — which might not warrant a significant investment in contemporary in-house mixers.

Additionally, through the reuse and refurbishment of equipment, producers encourage sustainable industrial methods. Prolonging the lifespan of current machinery and minimizing waste.

Conclusion

A Used Rubber Mixing Mill — Chandigarh generally serves as a practical, cost-effective. Adaptable solution for rubber-processing companies. although If chosen carefully and cared for well. A used two-roll mill can provide consistent mixing, versatility in materials, and dependable performance throughout production runs.

Nonetheless, the advantages entail obligations: careful inspection, upkeep, training for operators, and safety protocols are essential. With the proper measures, it can act as the foundation of your rubber compounding line for many years.

For more information Visit Here

Compression Molding

Compression Molding