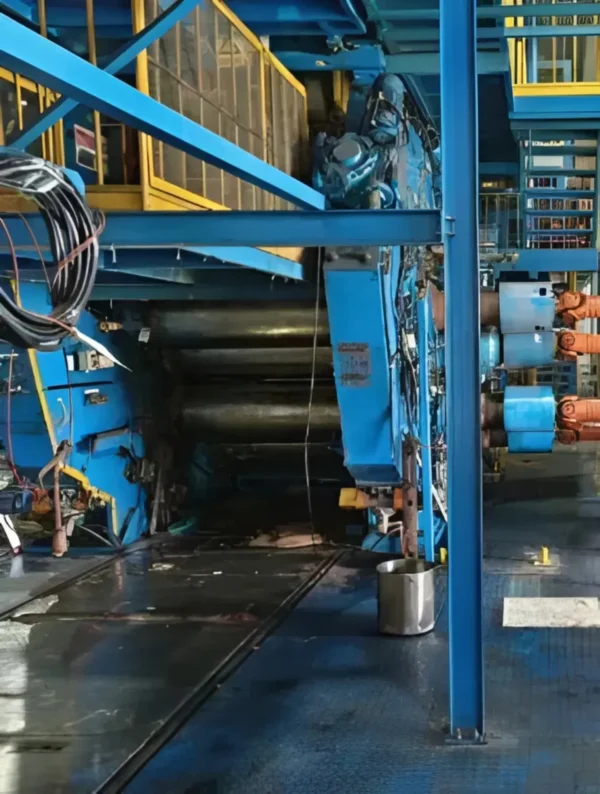

Buy | Sell Used for 1800 mm X 10000 mm YIYANG Used Rubber Conveyor Textile belt curing press for sale In India

A rubber conveyor belt production line involves various processes to create durable and efficient conveyor belts used in industries for material transportation. The production line typically includes several key stages:

- Raw Material Preparation: The process begins with selecting high-quality raw materials such as natural rubber, synthetic rubber, and reinforcing materials like fabric or steel cords.

- Compounding: The selected raw materials are then mixed and compounded to create a homogeneous rubber compound. This process is crucial to achieving the desired properties such as strength, flexibility, and resistance.

- Calendering: The compounded rubber is passed through calenders to form sheets of the required thickness. Calenders help in shaping and smoothing the rubber.

- Fabrication: Layers of fabric or steel cords are added to provide reinforcement and enhance the strength of the conveyor belt. The number and arrangement of these layers depend on the desired characteristics of the final product.

- Vulcanization: The assembled conveyor belt goes through a vulcanization process, involving heat and pressure. This step cures the rubber, creating a robust and durable structure.

- Cutting and Finishing: Once vulcanized, the conveyor belt is cut to the desired width and length. Additional finishing processes may include applying coatings for specific functionalities, such as resistance to abrasion or chemicals.

- Quality Control: Throughout the production line, rigorous quality control measures are implemented to ensure that the conveyor belts meet industry standards and customer specifications.

Different types of rubber conveyor belts cater to various industrial needs. Common types include:

- Flat Belt: Suitable for horizontal conveyance.

- Incline or Decline Belt: Designed for transporting materials at an angle.

- Cleated Belt: Features cleats or partitions for elevating materials.

- Sidewall Belt: Ideal for vertical conveying with attached side walls.

- Steel Cord Belt: Reinforced with steel cords for heavy-duty applications.

- Heat-Resistant Belt: Designed to withstand high temperatures.

- Oil-Resistant Belt: Resistant to oil and grease.

Various machines contribute to the production of rubber conveyor belts, such as mixing mills, calenders, extruders, and vulcanizing presses. The selection of machinery depends on the type and specifications of the conveyor belt.

At Vatsn Tecnic, we specialize in refurbished rubber processing machinery, offering cost-effective and reliable solutions for the production of conveyor belts and other rubber products. Our refurbished machinery ensures high-quality output and efficiency in rubber processing operations.

Contact us on +91 9310375229

For more Details Please Visit Our Website

https://vatsntecnic.com

| Parameter | unit | VAT-1800X | VAT-1800X | VAT-1600X | VAT-1600X | VAT-1400X |

| 12000*2 | 10000*2 | 10000*2 | 10000*1 | 10000*1 | ||

| Hot-plate size | mm | 1800*12000 | 1800*1000 | 1600*10000 | 1600*10000 | 1400*10000 |

| Total pressure | mn | 74 | 72 | 56 | 64 | 49 |

| Hot-plate unit pressure | mpa | 3.4 | 4 | 3.5 | 4 | 3.5 |

| Plunger diameter | mm | 500 | 500 | 450 | 500 | 450 |

| Plunger No | 18 | 18 | 18 | 18 | 18 | |

| Max plunger stroke | mm | 400 | 300 | 400 | 300 | 300 |

| Gripping strength | mn | 1.2 | 1.5 | 1.2 | 1.2 | 0.9 |

| Tension force | mn | 1.101.2 | 1.1 | 1 | 0.5 | 0.9 |

| Steam pressure | mpa | 0.63 | 0.6-0.8 | 0.63 | 0.6-0.8 | 0.63 |

| Cooling water pressure | mpa | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| controlling method | PLC | PLC | PLC | PLC | PLC |

Compression Molding

Compression Molding