Rubber Compression Molding provider in Tamil Nadu

Rubber Compression Molding Provider in Tamil Nadu | Industrial System Production Line

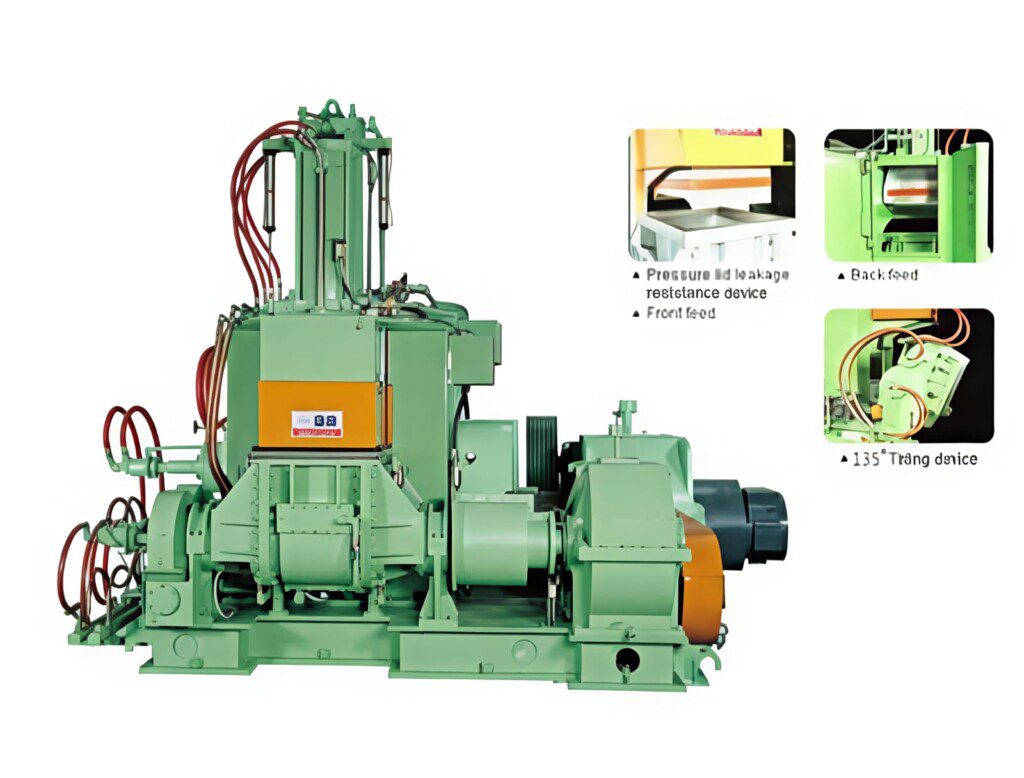

A reliable rubber compression molding provider in Tamil Nadu supports precision-based rubber component manufacturing.

Moreover, the region offers strong infrastructure for a controlled production process.

Therefore, manufacturers prefer partners skilled in industrial manufacturing steps.

In addition, structured production system development improves molding consistency.

As a result, equipment production units deliver stable output across the industrial system production line.

Moreover, Tamil Nadu enables smooth machine making process execution for rubber industries.

Benefits of a Reliable Production Process in Tamil Nadu | Industrial Manufacturing Steps

A reliable production process improves dimensional accuracy in rubber compression molding operations.

Moreover, structured industrial manufacturing steps reduce material wastage.

Therefore, manufacturers achieve consistent output quality.

In addition, production system development supports scalable manufacturing capacity.

As a result, the machine making process remains stable under continuous operation.

Moreover, equipment production units achieve longer service life within the industrial system production line.

Government Scheme for Setting Up a Trusted Supplier | Production System Development

Government initiatives strengthen production system development for rubber compression molding providers.

Moreover, policy frameworks encourage modernization of equipment production units.

Therefore, manufacturers gain confidence to invest in advanced machine making process technologies.

In addition, industrial manufacturing steps receive structured financial assistance.

As a result, industrial system production line expansion becomes more feasible.

Major Industrial Areas for Setting Up | Industrial System Production Line

Tamil Nadu offers multiple industrial regions suitable for rubber compression molding operations.

Moreover, these zones support smooth industrial manufacturing steps execution.

Therefore, suppliers benefit from skilled technical manpower availability.

In addition, logistics infrastructure supports equipment production units efficiency.

As a result, the production process remains time controlled and reliable.

Key industrial regions include Chennai, Coimbatore, Hosur, Tirunelveli, and Tiruppur clusters.

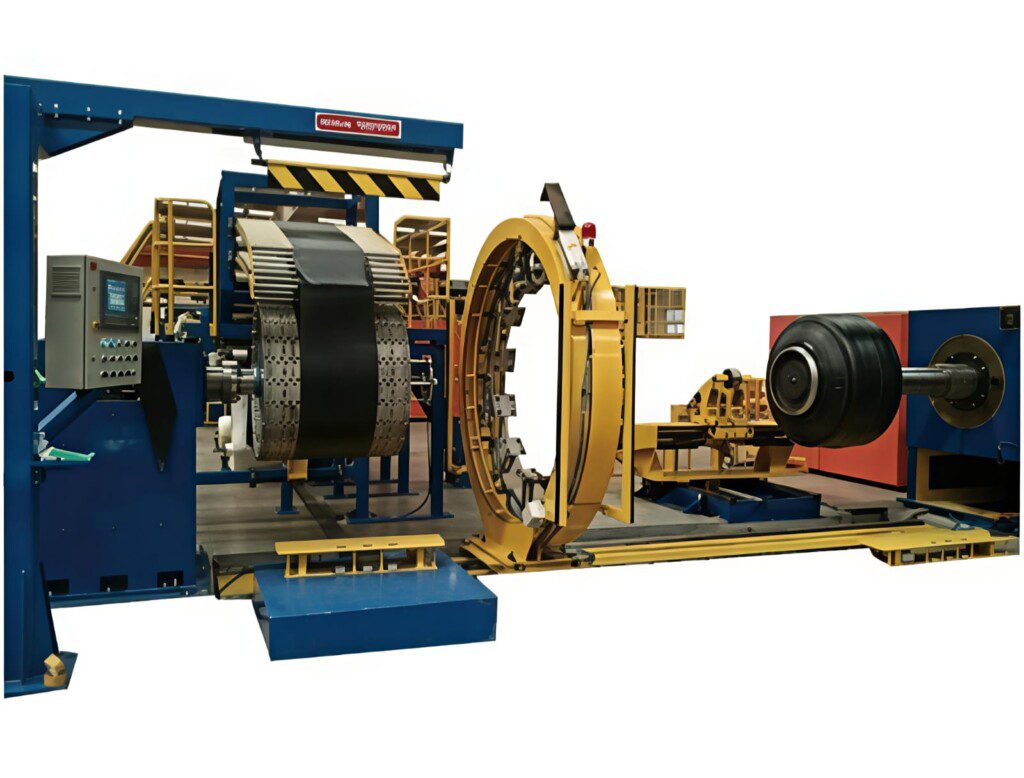

How Industrial Systems Are Made | Step-by-Step Manufacturing Process Using Production Process

Industrial systems follow a disciplined production process to ensure molding reliability.

Moreover, planning begins with production system development and mold design analysis.

Therefore, engineers define industrial manufacturing steps clearly.

In addition, fabrication follows a standardized machine making process.

As a result, equipment production units integrate smoothly into the industrial system production line.

Moreover, testing validates performance before commercial deployment.

Therefore, manufacturers receive dependable rubber compression molding solutions.

This approach aligns with principles seen in crocs slipper machine in surat working principle studies.

Why Choose VatsnTecnic? | Industrial Manufacturing Steps & Machine Making Process

VatsnTecnic delivers reliable solutions aligned with industrial manufacturing steps.

Moreover, the company focuses on a stable production process architecture.

Therefore, clients benefit from long-term production system development guidance.

In addition, technical teams support the complete machine making process lifecycle.

As a result, equipment production units maintain consistent performance.

Moreover, the industrial system production line remains optimized for durability.

The expertise reflects process discipline similar to crocs slipper machine in surat working principle analysis.

Tamil Nadu Government Schemes | Equipment Production Units & Production Process

Moreover, capital subsidy schemes support equipment production units

Therefore, MSME incentives strengthen production process investment

In addition, technology upgradation programs improve machine making process

As a result, industrial manufacturing steps become cost efficient

Moreover, infrastructure support accelerates industrial system production line growth

A dependable rubber compression molding provider in Tamil Nadu ensures consistent industrial output.

Moreover, structured industrial manufacturing steps reduce operational risks.

Therefore, production system development remains sustainable over time.

In addition, optimized equipment production units enhance productivity.

As a result, the industrial system production line delivers reliable performance.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For more information Visit Here

Compression Molding

Compression Molding