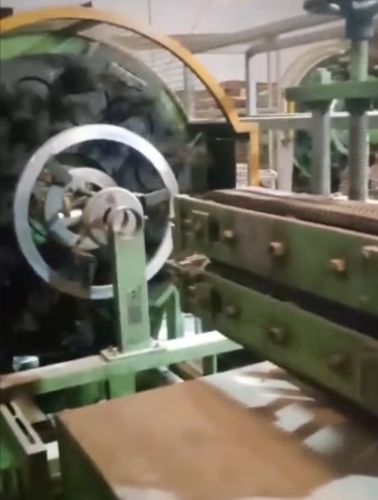

25 LTR Rubber Dispersion Kneader Machine

Manufacturing Process in Maharashtra | Industrial Production System Development

- The Manjeet Singh Model 25 Litre machine is designed to meet 21st Century industrial manufacturing requirements in many areas.

- Maharashtra continues to be one of the most important states for developing a production line for an industrial system in India.

- The State of Maharashtra has the infrastructure, skilled workforce, and policy environment to establish many sites for manufacturing equipment.

- This provides manufacturers with the ability to develop scalable systems of production at this location.

- Furthermore, continued growth within the industries, in turn, increases efficiency and the quality of output of machines produced by these manufacturers.

- The production processes developed in Maharashtra emphasize long-term reliability, consistency of output, and precision.

- Consequently, the industries located here enjoy improved efficiency within their operations as well as greater competitive advantages.

- Additionally, the State of Maharashtra encourages the use of modern technology in its advanced manufacturing processes.

- This blog provides a clear understanding of the entire manufacturing process from start to finish, as well as the benefits of using the various schemes, types of industrial zones, etc.

- This will provide investors and manufacturers with the knowledge to make the best decisions possible.

Benefits of a Reliable Production Process in Maharashtra

- Moreover, strong infrastructure supports efficient industrial manufacturing steps.

- Therefore, skilled manpower improves the machine making process accuracy.

- In addition, logistics connectivity reduces delays across the industrial system production line.

- As a result, equipment production units maintain consistent output quality.

- Moreover, policy support strengthens long-term production system development.

- Therefore, industries scale faster with stable production process frameworks.

Government Scheme for Setting Up a Trusted Supplier of Rubber Dispersion Kneader Machines in Delhi

- Moreover, MSME schemes offer financial assistance for industrial manufacturing steps.

- Therefore, capital subsidies reduce initial equipment production unit costs.

- In addition, credit guarantee schemes support easy loan access.

- As a result, technology upgradation programs improve machine making process efficiency.

- Moreover, industrial development policies encourage production system development growth.

Major Industrial Areas for Setting Up Manufacturing Units in Maharashtra

- Moreover, MIDC Pune supports advanced industrial system production line setups.

- Therefore, Aurangabad industrial zone enables efficient production process operations.

- In addition, Nashik MIDC offers space for equipment production units.

- As a result, Nagpur MIHAN attracts large-scale production system development projects.

- Moreover, Thane-Belapur belt supports high-capacity industrial manufacturing steps.

How Industrial Systems Are Made | Step-by-Step Manufacturing Process

Concept Planning and Design

First, engineers define system capacity for the 25 ltr make Manjeet Singh model.

Moreover, design teams focus on durability and operational efficiency.

Therefore, CAD tools optimize the industrial system production line layout.

Raw Material Selection

Next, manufacturers choose certified metals and components.

In addition, material testing ensures long-term production process stability.

As a result, equipment production units achieve higher reliability.

Component Fabrication

Then, cutting and machining begin using precision tools.

Moreover, controlled processes reduce wastage during industrial manufacturing steps.

Therefore, the machine making process remains cost-effective.

Assembly Process

After fabrication, parts move to structured assembly stations.

In addition, technicians follow standardized production system development protocols.

As a result, alignment and fitting accuracy improves.

Electrical and Control Integration

Next, control panels and sensors are installed carefully.

Moreover, automation improves industrial system production line performance.

Therefore, operators gain better control and safety.

Testing and Quality Inspection

Then, systems undergo performance and load testing.

In addition, quality teams verify every production process parameter.

As a result, defects reduce significantly before dispatch.

Finishing and Surface Treatment

After testing, finishing improves corrosion resistance.

Moreover, coatings extend equipment production unit lifespan.

Therefore, machines perform better in industrial environments.

Packaging and Dispatch

Finally, machines are packed using protective materials.

In addition, logistics planning ensures safe industrial manufacturing steps completion.

As a result, customers receive ready-to-install systems.

Why Choose VatsnTecnic? for Industrial Machine Manufacturing

VatsnTecnic delivers reliable industrial system production line solutions.

Moreover, the company follows structured production system development practices.

Therefore, clients receive consistent and high-quality machinery.

Key Benefits

Moreover, advanced designs support efficient machine making process outcomes.

In addition, systems match global industrial manufacturing steps standards.

As a result, productivity and safety improve.

Technical Support

Moreover, expert engineers provide installation and training support.

Therefore, production process disruptions reduce significantly.

Reliability

In addition, strict testing ensures long-term equipment production unit reliability.

As a result, maintenance costs remain controlled.

Scalability

Moreover, modular designs support future production system development expansion.

Therefore, businesses grow without major reinvestment.

Industry Experience

In addition, years of experience strengthen industrial manufacturing steps execution.

As a result, clients trust VatsnTecnic solutions consistently.

The 25 ltr make Manjeet Singh system fits diverse industrial applications efficiently.

Moreover, Maharashtra offers the ideal ecosystem for industrial system production line growth.

Therefore, manufacturers achieve operational excellence and market competitiveness.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For more information Visit Here

You must be logged in to post a review.

Compression Molding

Compression Molding

Reviews

There are no reviews yet.