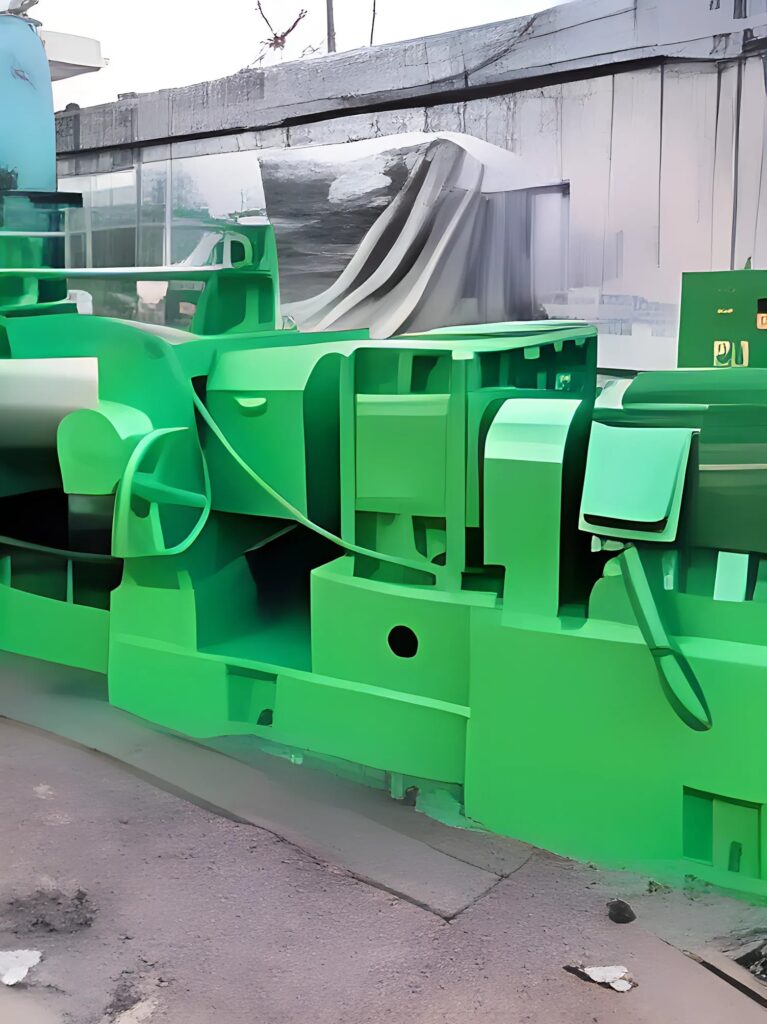

Two Roll Rubber Mixing Mills with Bearings

Buy | Sell Used Open Rubber Mixing Mill 16 X 42 Motor 60 Hp

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

Overall dimension(mm) | L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

Buy | Sell Used Two Roll Rubber Mixing Mill 16 X 42 Motor 60 Hp

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

Overall dimension(mm) | L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

Buy| Sell Used Rubber Mixing Mill

Introducing our high-quality, pre-owned Rubber Mixing Mill, meticulously designed to meet the demands of the rubber processing industry. This robust and reliable equipment is an exceptional addition to any manufacturing facility, offering unparalleled efficiency and precision in the blending and refining of rubber compounds.Key Features:

- Durable Construction: Crafted from premium-grade materials, this used mixing mill ensures longevity and dependable performance, even after extensive use.

- Versatile Mixing Capabilities: Engineered with precision, it facilitates the thorough mixing and dispersion of rubber compounds, additives, and pigments, enhancing product consistency and quality.

- Efficient Processing: Equipped with advanced controls and mechanisms, this machine streamlines the blending process, reducing operational time and maximizing productivity.

- Customizable Operations: The adjustable settings and controls allow operators to fine-tune the mixing parameters, ensuring tailored outcomes to meet specific production requirements.

- Safety Features: Engineered with safety in mind, this mixing mill comes with built-in safety measures to protect operators during operation, minimizing risks and ensuring a secure working environment.

- Cost-Effective Solution: Investing in a quality, pre-owned mixing mill offers a cost-effective alternative without compromising on performance or reliability, providing excellent value for your business.

Buy| Sell Used Uni-Drive Rubber Mixing Mill Size of 16 X 42

<td>305307603096015-20<td>13<tr>GMX-12”X30”12&amp;lt;/tr><td>mmInchmm</strong>HP</strong>RPMKg/H</strong>R</strong><p>369154096025-30<td>35-40<td>100-150650</td>

84</tr><td>GMX-14”X36”</tr>-16”X42”/td></tr><td>960<td>60<</td><tbody>strong>Model<strong>Chilled roll barrel dimensionDrive electric motor</strong></strong>Batch capacity</td><td>457/td><td>22

| < | ||||||||||||||||

| Diameter | Length | |||||||||||||||

| Inch | ||||||||||||||||

| GMX-6”X13” | 6 | 152 | 330 | 7.5 | 960 | 2-3 | ||||||||||

| GMX-8”X18” | 8 | 203 | 18 | 10 | 960 | 4-5 | ||||||||||

| <strong>GMX-10”X24”</td> | 10 | 254 | 24 | 610 | 20 | 960 | 6-9 | 14 | 355 | GMX | 16 | 406 | 42</td> | 1066 | 60 | 960 |

| GMX-18”X48”</strong></td> | 18 | 457 | 48 | 1220</td> | 75< | 40-50 | ||||||||||

| <strong>GMX-22”X60” | 560</td></td> | 1524 | 960 | 60-80 | <strong>GMX-26”X84” | 26 | 2134 | 200-250 | 960 | 90-105 | ||||||

| GMX-30”X100”</td> | 30 | 762</td> | 100 | 2540 | 300-350 | 960 | 125-200 | |||||||||

Compression Molding

Compression Molding