How to Choose the Best Used Rubber Machinery for Your Business

Every business today in the competitive manufacturing world needs high-quality used rubber machinery. The right approach will help you find well-maintained machines that fit your production needs and budget perfectly. However, selecting the best-used rubber machinery requires some planning and knowledge in researching essential factors. Read along to learn how to make the right decision when buying used rubber machinery.

1. Determination of Production Needs –

Requirements Market production needs and requirements.

- What rubber do you want to produce? Depends on the specific rubber machinery you’d want for your tires, seals, or other industrial products.

- What is your capacity requirement? When trying to determine what to make, think about how much you will make to fulfill the operational demand that it supports at the machine level.

- How much room do you have? Some rubber machinery takes up quite a bit of room, so be sure to consider your space installation and operation maintenance of the machinery.

Defining these needs will allow you to narrow your choices to a preferred type of machinery, whereas if you are unclear of your needs then you will look at everything that’s out there.

2. Types of Used Rubber Machinery Offered –

We offer a wide range of used rubber machinery, from mixing mills to vulcanizers, including extruders and calenders. Each type of equipment is briefly described below:

- Rubber Mixing Mills: They mix rubber compounds with other substances to achieve the desired consistency in the rubber compound.

- Rubber Extruders: These shape rubber continuously, yielding hoses, seals, or profiles.

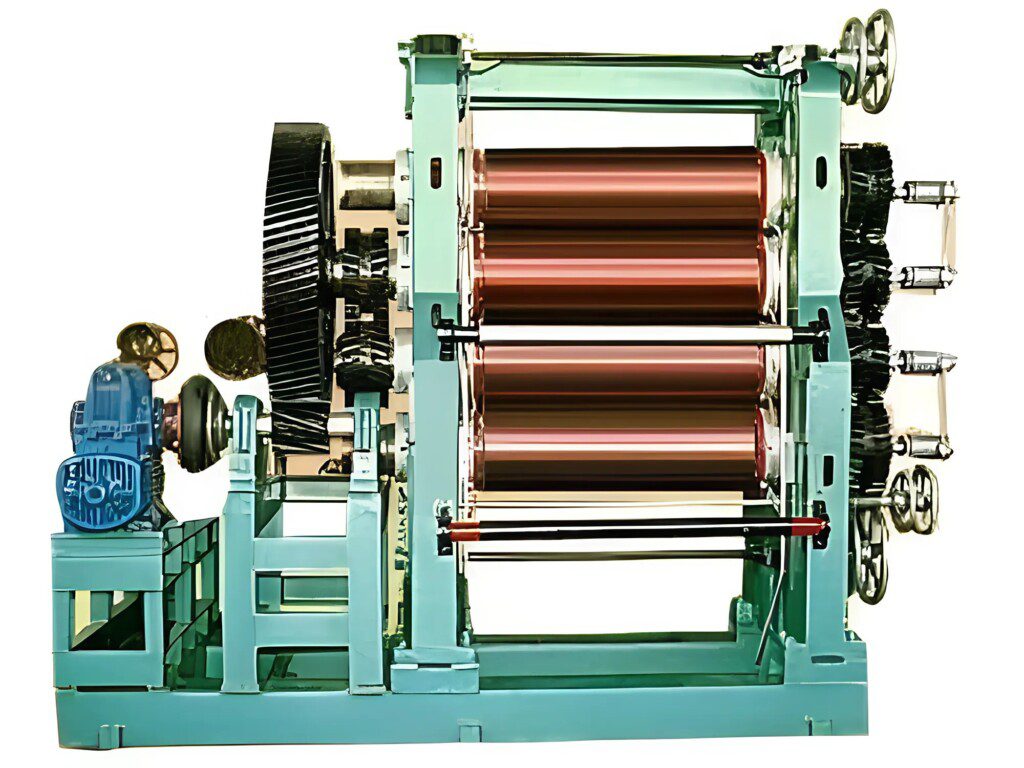

- Rubber Calenders: They are used in the process of manufacturing rubber into thin sheets, mainly used in the tire industry as well as other large dimensions.

- Rubber Vulcanizers: These are the ones used for heating and chemical treatment of rubber to produce its hardness and elasticity.

Thus with the idea of what each is made for, you will be in a better position to choose what applies to you for your production.

3. Machinery Condition Appraisal –

Buy used machines, and that is done very carefully with inspection. The whole process prevents concealed issues and assures that you are investing in the equipment that shall be there with you long-term. Consider the following:

- Wear and Tear: Look for signs of wear on rollers, bearings, and motors, which are some of the most crucial components.

- Maintenance records: Keep maintenance and service records accessible to confirm that the machine has undergone regular servicing.

- Functional Efficiency: If you are lucky, request them to run it or demonstrate the machine, so you get to see how it works. In this way, you shall test whether it runs smoothly or not and whether it has the performance expected from it.

Carry with you a technician or machinery expert if not conversant with machinery mechanics.

4. Brand and Model Research –

The quality and the availability of parts in the brand and model could be quite different when making a purchase. Top brands excel in durability, reliability, and ease of maintenance. Explore the leading industrial players, review the available parts for specific models, and ensure you can find repair and replacement options as needed.

5. Age of the machinery –

Older models can be nearly as efficient as new ones but may have drawbacks like higher energy use or lack of modern automation. Compare their pros and cons, assess compatibility with current production standards, and consider if upgrades are necessary.

6. Price and Option Comparison

Price is probably the first factor in that buying decision, although with the lowest price in mind comes more value added by these three:

- The condition of the machine

- Availability of parts

- Vendor reputation

A reliable seller may cost more but ensures a safe, fully functional unit in top condition. Look for sellers offering guarantees or service contracts for added peace of mind.

7. After-sales support and Warranty Available –

Other dealers will offer you service support or even a limited warranty with second-hand equipment. This provides a significant advantage, as you can rely on your machine’s performance and receive prompt service if any issues arise. Ask if the seller offers support after sales, training, or parts for after-sales maintenance.

8. Buy from a Reliable Vendor –

You must purchase from a reliable supplier. Reliable suppliers have their reputation to protect, thus testing, refurbishing, and certifying machines before selling them. It becomes prudent to look for a supplier with good customer feedback and good experience in the supply chain.

Conclusion –

Careful planning and research are key to selecting the best-used rubber machinery to improve production. Identifying your needs allows you to assess machine quality and reliability, guiding a cost-effective purchase that boosts production efficiency. That’s how you have been reading some fantastic tips for finding the best machinery for business.

For More Information Visit Here

Compression Molding

Compression Molding