Rubber Compression Molding Mizoram

Rubber Compression Molding in Mizoram | Industrial Manufacturing Growth Guide

Rubber Compression Molding in Mizoram supports structured industrial expansion across emerging manufacturing clusters.

Moreover, this technology strengthens local production capacity and long-term industrial sustainability.

Therefore, manufacturers increasingly adopt this molding method for consistent quality output.

In addition, Mizoram offers policy advantages for equipment production units and industrial system production line setups.

As a result, this manufacturing approach becomes vital for modern industrial manufacturing steps.

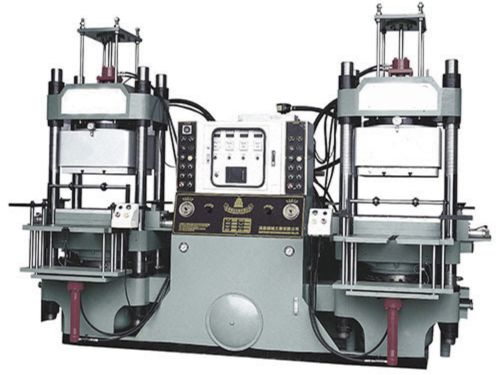

This molding technology enables controlled shaping using pressure and heat efficiently.

Moreover, the production process supports uniformity across rubber component manufacturing.

Therefore, industries achieve predictable outcomes using structured production system development.

In addition, the machine making process ensures repeatable and scalable manufacturing operations.

Benefits of a Reliable Production Process in Maharashtra

A reliable production process improves efficiency and output quality across rubber manufacturing sectors.

Moreover, structured industrial manufacturing steps reduce operational downtime significantly.

Therefore, stable industrial system production line performance improves consistency

Moreover, optimized production system development increases capacity utilization

In addition, advanced machine making process enhances dimensional accuracy

As a result, equipment production units deliver consistent batch quality

Therefore, standardized production process reduces maintenance costs

Moreover, scalability improves for long-term manufacturing growth

Government Scheme for Setting Up a Trusted Supplier

Government schemes actively promote industrial investments across northeastern states.

Moreover, industrial development support accelerates equipment production units expansion.

Therefore, MSME schemes support production process funding

Moreover, capital subsidies enhance industrial manufacturing steps adoption

In addition, technology upgradation programs improve machine making process efficiency

As a result, infrastructure incentives strengthen industrial system production line deployment

Therefore, export promotion schemes benefit manufacturing suppliers

Major Industrial Areas for Setting Up Manufacturing Units

Mizoram offers focused zones suitable for industrial expansion.

Moreover, these regions support integrated production system development.

Therefore, Zuangtui Industrial Estate supports industrial manufacturing steps

Moreover, Kolasib Industrial Area enables machine making process facilities

In addition, Lunglei Growth Centre attracts equipment production units

As a result, Champhai Industrial Zone supports industrial system production line setups

Therefore, Sairang Industrial Hub encourages manufacturing investments

How Industrial Systems Are Made | Step-by-Step Manufacturing Process

The manufacturing workflow follows defined industrial manufacturing steps for reliable outcomes.

Moreover, each production process stage ensures precision and efficiency.

Raw rubber compounds enter the industrial system production line first.

Therefore, material inspection ensures consistent machine making process standards.

Next, operators prepare molds using controlled surface treatment methods.

Moreover, this step improves product finish during compression molding operations.

Measured rubber charges move into heated molds carefully.

Therefore, compression pressure activates structured production system development.

Heat and pressure shape components accurately during the production process.

Moreover, timing control improves industrial manufacturing steps reliability.

After curing, operators release molded parts systematically.

As a result, equipment production units maintain repeatable quality output.

Finally, inspection verifies dimensions and mechanical performance.

Therefore, this molding method ensures long-term industrial value.

Why Choose VatsnTecnic? | Industrial Machine Manufacturing Expertise

VatsnTecnic delivers advanced industrial machine manufacturing solutions.

Moreover, the company supports complete production system development.

VatsnTecnic provides precision-driven machine making process expertise.

Therefore, clients gain reliable industrial system production line performance.

Moreover, robust equipment production units ensure operational durability

Therefore, technical support strengthens industrial manufacturing steps

In addition, customization improves production efficiency

As a result, maintenance response remains fast and reliable

Moreover, quality assurance enhances long-term production process stability

Delhi Government Schemes Supporting Industrial Manufacturing

Delhi provides strong policy support for industrial system suppliers.

Moreover, these schemes accelerate industrial system production line investments.

Therefore, startup incentives support equipment production units

Moreover, skill development programs improve machine making process expertise

In addition, power tariff subsidies reduce production process costs

As a result, infrastructure assistance strengthens industrial manufacturing steps

Therefore, innovation grants enhance production system development

Rubber Compression Molding in Mizoram drives structured industrial growth effectively.

Moreover, strong policy support encourages sustainable equipment production units.

Therefore, manufacturers achieve scalable industrial system production line success.

In addition, reliable production process planning ensures long-term profitability.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For more information Visit Here

Compression Molding

Compression Molding