Rubber Vacuum Molding Manufacturing Kerala

Rubber Vacuum Molding in Kerala Using Advanced Production Process

Rubber Vacuum Molding in Kerala supports precision-driven industrial manufacturing needs.

Moreover, Kerala offers skilled labor, port access, and industrial-friendly policies.

Therefore, manufacturers prefer this region for production system development.

In addition, rubber vacuum molding improves dimensional accuracy and product durability.

As a result, industries achieve stable industrial system production lines.

Rubber vacuum molding uses heat and vacuum pressure for controlled shaping.

Moreover, this production process reduces material waste significantly.

Therefore, equipment production units achieve higher efficiency levels.

In addition, the machine making process supports repeatable output quality.

Benefits of a Reliable Production Process in Maharashtra Using Industrial Manufacturing Steps

Although Kerala focuses on rubber molding, Maharashtra strengthens the manufacturing ecosystem.

Moreover, Maharashtra supports large-scale industrial manufacturing steps.

Therefore, businesses gain supply chain stability and growth.

Moreover, a reliable production process ensures consistent rubber product output.

Therefore, industries reduce downtime across industrial system production lines.

In addition, advanced machine making processes improve productivity.

As a result, equipment production units deliver faster turnaround times.

Moreover, skilled manpower supports optimized industrial manufacturing steps.

Therefore, logistics networks enhance raw material availability.

Government Scheme for Setting Up a Trusted Supplier Using Production System Development

Government initiatives encourage rubber vacuum molding investments.

Moreover, policies focus on structured production system development.

Therefore, trusted suppliers gain competitive advantages.

Moreover, MSME schemes support equipment production units financially.

Therefore, capital subsidies reduce machine making process expenses.

In addition, industrial development support improves infrastructure access.

As a result, training programs strengthen industrial manufacturing steps.

Moreover, export incentives support global market entry.

Major Industrial Areas for Setting Up Production Process and Equipment Production Units

Kerala offers multiple industrial zones for rubber vacuum molding.

Moreover, these zones support industrial system production lines.

Therefore, manufacturers gain operational efficiency.

Moreover, KINFRA Parks support advanced production processes.

Therefore, Kochi Industrial Area attracts export-driven equipment production units.

In addition, Palakkad Zone supports scalable machine making processes.

As a result, Kannur Industrial Area boosts industrial manufacturing steps.

Moreover, Thiruvananthapuram Zones support production system development.

How Industrial Systems Are Made | Step-by-Step Manufacturing Process Using Industrial System Production Line

Rubber vacuum molding follows defined industrial manufacturing steps.

Moreover, each step strengthens the production process.

Therefore, manufacturers maintain quality consistency.

First, engineers design molds during production system development.

Moreover, precise planning improves the machine making process.

Therefore, mold accuracy enhances final product reliability.

Next, operators prepare rubber compounds carefully.

In addition, material testing supports consistent industrial manufacturing steps.

As a result, defects reduce across the industrial system production line.

Then, workers load rubber sheets into prepared molds.

Moreover, vacuum pressure removes air efficiently.

Therefore, uniform shaping occurs during the production process.

After that, controlled heating cures rubber materials.

In addition, precise temperatures support equipment production units performance.

As a result, products gain strength and flexibility.

Next, gradual cooling stabilizes molded components.

Moreover, cooling supports dimensional accuracy.

Therefore, consistency improves across industrial manufacturing steps.

Finally, inspection teams test finished rubber products.

In addition, quality checks validate production system development goals.

As a result, industries deliver reliable rubber components.

Why Choose VatsnTecnic? for Industrial Machine Manufacturing and Production Process Excellence

VatsnTecnic delivers complete industrial machine manufacturing solutions.

Moreover, the company supports end-to-end production system development.

Therefore, clients achieve efficient industrial system production lines.

Moreover, VatsnTecnic provides advanced machine making processes.

Therefore, clients receive durable equipment production units.

In addition, expert engineers support industrial manufacturing steps.

As a result, technical support ensures uninterrupted production processes.

Moreover, reliability defines every industrial system production line delivered.

Delhi Government Schemes Supporting Industrial Manufacturing Steps and Production Process

Delhi government policies support industrial machine manufacturing growth.

Moreover, schemes encourage structured production system development.

Therefore, suppliers gain financial and operational benefits.

Moreover, startup policies support equipment production units expansion.

Therefore, tax benefits reduce machine making process costs.

In addition, infrastructure schemes improve industrial system production lines.

As a result, skill programs strengthen industrial manufacturing steps.

Moreover, financial incentives support advanced production processes.

Rubber Vacuum Molding in Kerala continues driving industrial progress.

Moreover, advanced production processes ensure long-term sustainability.

Therefore, industries achieve quality, scalability, and profitability.

In addition, policy support accelerates production system development.

As a result, manufacturers adopt efficient industrial manufacturing steps confidently.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For more information Visit Here

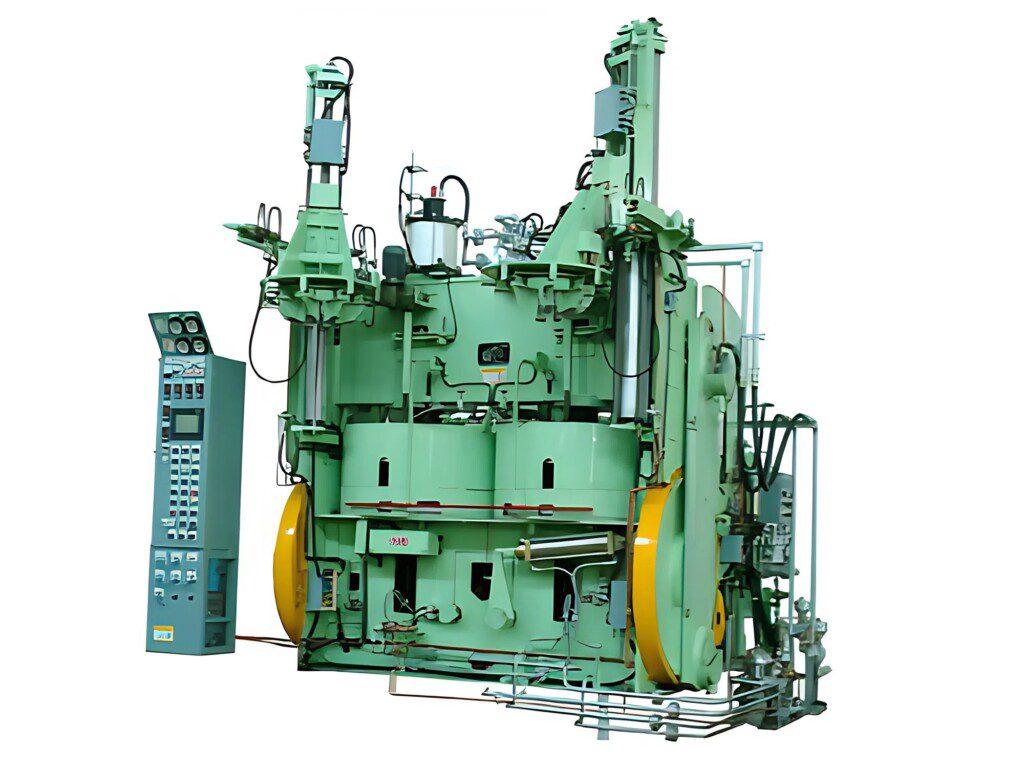

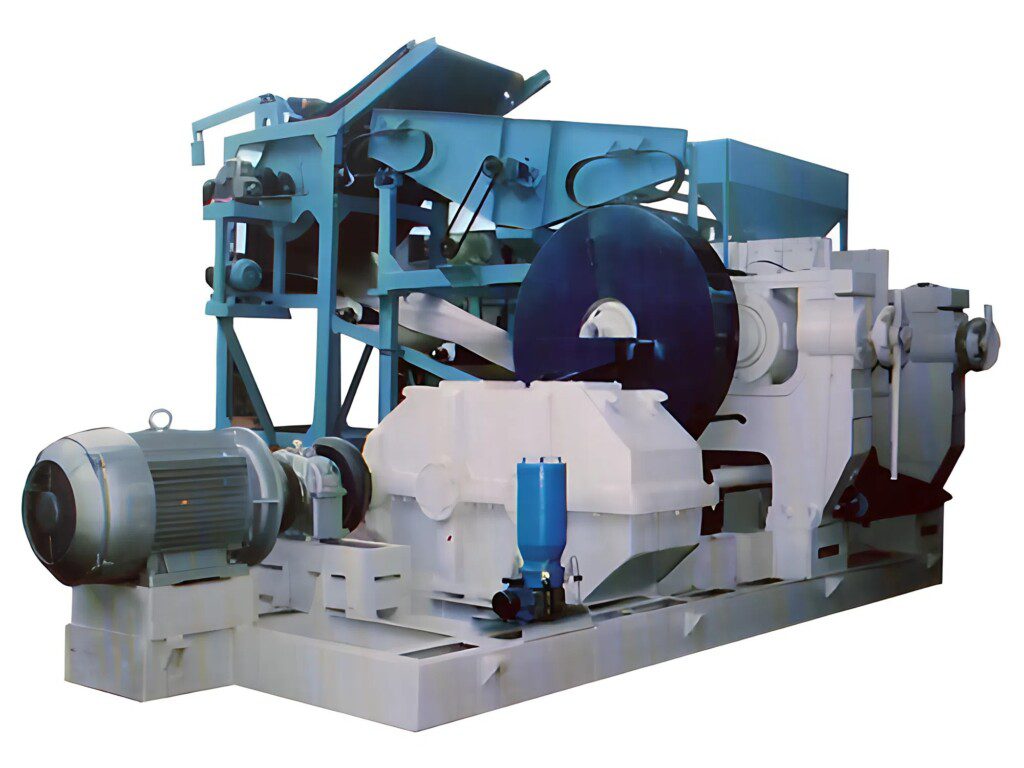

Compression Molding

Compression Molding