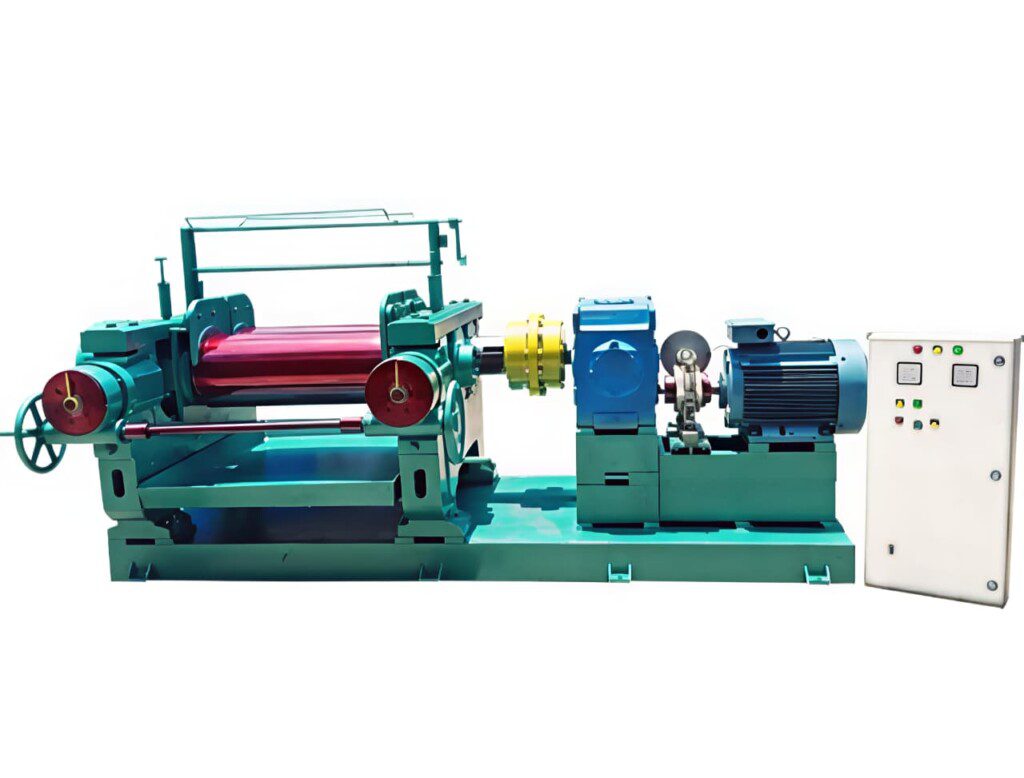

Used Rubber Mixing Mill Bhopal for Industrial Manufacturing

Old Rubber Mixing Mill Bhopal – Reliable Used Rubber Mixing Mill for Industrial Manufacturing

- An Old Rubber Mixing Mill Bhopal offers reliable performance for rubber processing industries.

Moreover, manufacturers prefer used rubber mixing mills to reduce capital investment.

Therefore, small and medium enterprises gain faster production stability. - In addition, Bhopal supports industrial growth through skilled labor availability.

As a result, production systems operate smoothly with reduced downtime.

Furthermore, refurbished rubber mixing mills ensure consistent compound quality. - An old rubber mixing mill suits startups and expanding manufacturing units.

Therefore, industrial manufacturing steps remain efficient and controlled.

Benefits in Rubber Manufacturing Systems

An Rubber Mixing Mill Bhopal delivers multiple operational benefits.

Moreover, it ensures uniform rubber blending during the production process.

Key benefits of setting up an old rubber mixing mill include:

- Lower machine acquisition cost improves cash flow.

- Moreover, setup time remains shorter compared to new installations.

- In addition, maintenance costs stay manageable with local service support.

- Therefore, production system development accelerates quickly.

- As a result, profitability improves within shorter operational cycles.

Used rubber mixing mills support steady industrial manufacturing steps.

Furthermore, operators adapt easily due to simple machine controls.

Manufacturing Steps

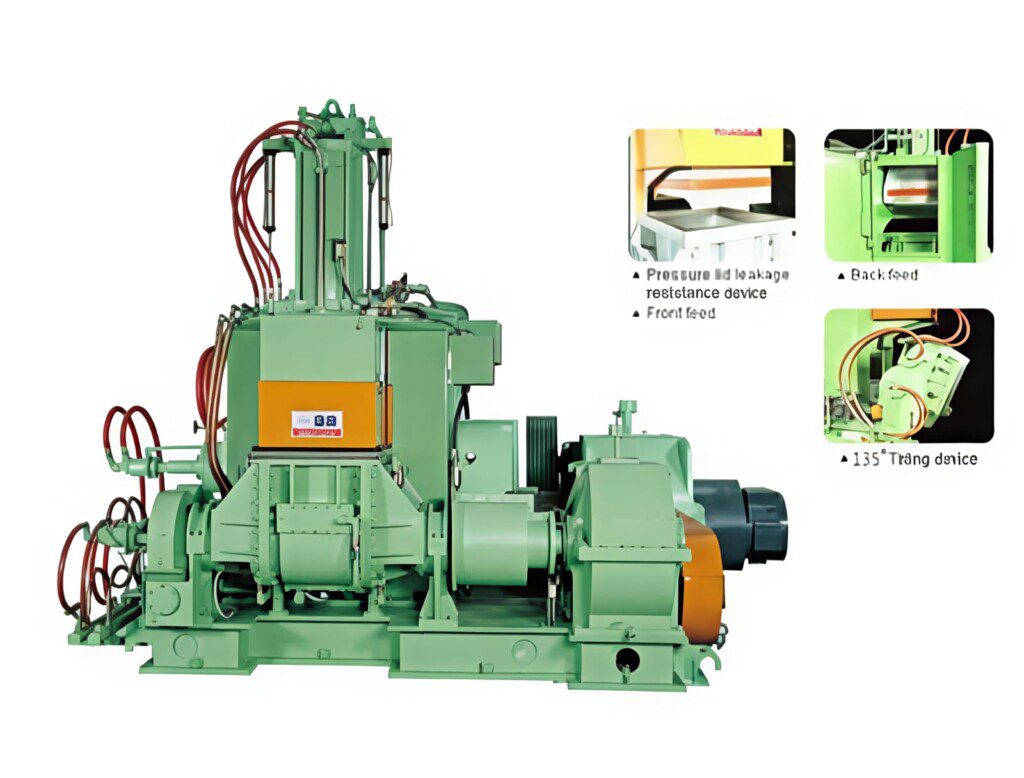

- An Old Rubber Mixing Mill Bhopal ensures controlled rubber mastication.

Moreover, rollers maintain uniform pressure across rubber batches.

Therefore, compound consistency improves throughout the production process. - In addition, mills handle natural and synthetic rubber efficiently.

As a result, manufacturing flexibility increases across product lines. - Industrial production benefits from predictable output quality.

Furthermore, production system development stays aligned with demand cycles.

Government Scheme for Trusted Supplier Setup

Government schemes encourage Old Rubber Mixing Mill Bhopal installations.

Moreover, MSME programs support trusted supplier development.

Five government scheme benefits for setting up a trusted supplier:

- Capital subsidy under MSME manufacturing schemes.

- Moreover, low-interest loans through SIDBI assistance.

- In addition, credit guarantee support for equipment purchase.

- Therefore, skill development programs improve workforce efficiency.

- As a result, technology upgradation incentives reduce operational risk.

These schemes strengthen production system development.

Furthermore, suppliers gain long-term industrial credibility.

Manufacturing Steps in Industrial Zones

An Old Rubber Mixing Mill Bhopal fits well within industrial clusters.

Moreover, Bhopal offers infrastructure suitable for rubber processing units.

Five major industrial areas for manufacturing steps include:

- Mandideep Industrial Area for heavy manufacturing.

- Moreover, Govindpura Industrial Area supports small industries.

- In addition, Pilukhedi Industrial Zone enables expansion.

- Therefore, Bhopal SEZ improves logistics efficiency.

- As a result, Misrod Industrial Area supports machinery operations.

These areas simplify industrial manufacturing steps.

Furthermore, raw material sourcing becomes easier.

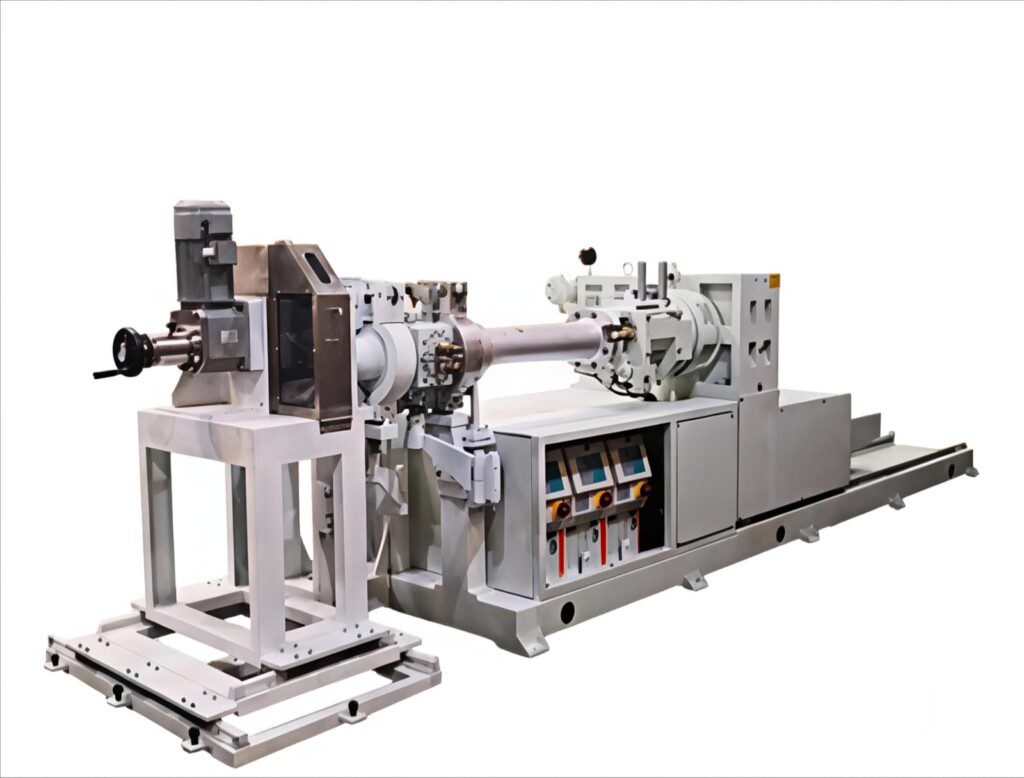

Installation Process Explained

- Installation of an Old Rubber Mixing Mill Bhopal follows defined steps.

Moreover, foundation preparation ensures vibration-free operation.

Therefore, machine alignment improves roller lifespan. - In addition, electrical synchronization ensures energy efficiency.

As a result, production process stability increases. - Operators receive basic training during commissioning.

Furthermore, production system development begins immediately after setup.

Long-Term Manufacturing

- Regular maintenance keeps an Old Rubber Mixing Mill Bhopal productive.

Moreover, scheduled lubrication reduces roller wear.

Therefore, downtime remains minimal during peak production. - In addition, bearing inspection ensures operational safety.

As a result, manufacturing steps continue without interruptions. - Preventive maintenance supports consistent production process quality.

Furthermore, equipment reliability strengthens supplier reputation.

Why Choose VatsnTecnic for Manufacturing Systems

VatsnTecnic designs and refurbishes industrial machinery professionally.

Moreover, every unit follows a structured machine making process.

Why choose VatsnTecnic for old rubber mixing mills:

- Precision engineering improves roller performance.

- Moreover, strict quality checks ensure production reliability.

- In addition, machines support long-term production system development.

- Therefore, customers receive cost-effective industrial solutions.

- As a result, manufacturing efficiency improves consistently.

VatsnTecnic supports how machines are made and tested thoroughly.

Furthermore, technical guidance ensures smooth industrial manufacturing steps.

Conclusion:

A rubber mixing solution in Bhopal supports affordable rubber manufacturing.

Moreover, it strengthens production process efficiency.

Therefore, manufacturers achieve sustainable growth.

In addition, government schemes reduce financial burden.

As a result, trusted supplier development becomes achievable.

Choosing the right machine partner remains essential.

Furthermore, VatsnTecnic delivers reliability, performance, and industrial expertise.

For more information Visit Here

https://www.indiamart.com/vatsntecnic/profile.html

Compression Molding

Compression Molding