Preowned Machinery Rubberized Fabric Production

In the realm of industrial fabric production, the Rubberized Fabric Sheet Making Machine stands as a vital player, ensuring the efficient and precise creation of rubber-coated fabrics. This innovative technology has become a cornerstone in various industries, from automotive to fashion and beyond. In this blog post, we delve into the intricacies of Rubberized Fabric Sheet Making Machines, the machines involved in the process, and the market benefits and future aspects associated with this revolutionary technology. Additionally, we’ll explore the advantages of choosing Vatsn Tecnic, a leading provider of used, preowned, and secondhand Rubberized Fabric Sheet Making Machines.

What is a Rubberized Fabric Sheet Making Machine?

A Rubberized Fabric Sheet Making Machine is a specialized piece of equipment designed to coat fabric with rubber, creating a durable and versatile material with a wide range of applications. The process involves feeding fabric through the machine, where it undergoes a series of treatments to apply a rubber layer evenly. This technology enhances the fabric’s strength, water resistance, and overall durability, making it ideal for diverse industrial uses.

Machines Used in the Process-

The production of rubberized fabric sheets involves a combination of sophisticated machines to achieve the desired results. Key machines used in this process include:

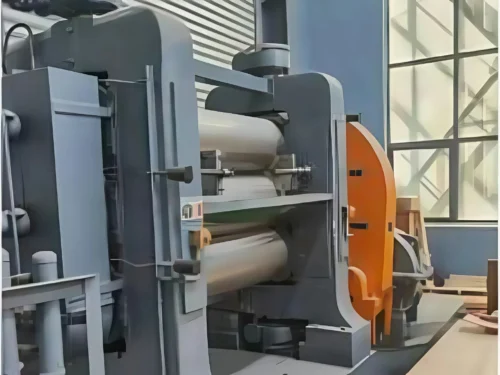

1. Fabric Coating Machine: This is the primary machine responsible for applying a uniform layer of

rubber onto the fabric.

rubber onto the fabric.

2. Drying System: After the rubber coating, the fabric goes through a drying system to ensure the coating adheres properly and efficiently.

3. Calender Machine: This machine imparts specific textures or patterns to the rubberized fabric, adding further functionality and aesthetic appeal.

4. Cutting and Finishing Equipment: Once the rubberized fabric is ready, specialized cutting and finishing machines trim it to the required size and shape.

Market Benefits and Future Aspects-

The market for rubberized fabric sheets is experiencing significant growth, driven by increased demand across various industries. The benefits of using rubberized fabric include enhanced durability, resistance to weather conditions, and improved performance in diverse applications. As industries continue to prioritize sustainability, the recyclability and eco-friendliness of rubberized fabric further contribute to its market appeal.

Looking ahead, the future of rubberized fabric production appears promising. Advancements in material science and manufacturing technologies are likely to result in more efficient and sustainable production processes. As industries evolve, the demand for innovative materials, such as rubberized fabric, is expected to rise, creating new opportunities for manufacturers and suppliers.

Vatsn Tecnic: Your Trusted Partner in Rubberized Fabric Sheet-Making Machines-

Vatsn Tecnic stands out as a reputable provider of used, preowned, and secondhand Rubberized Fabric Sheet Making Machines. Choosing Vatsn Tecnic offers several key advantages:

1. Cost-Effective Solutions: Acquiring secondhand machines from Vatsn Tecnic allows businesses to enjoy cutting-edge technology at a fraction of the cost of new equipment.

2. Quality Assurance: Vatsn Tecnic thoroughly inspects and refurbishes all machines, ensuring they meet high-quality standards and deliver reliable performance.

3. Expertise and Support: With years of experience in the industry, Vatsn Tecnic provides expert guidance and support to clients, helping them make informed decisions and maximize the efficiency of their operations.

Conclusion-

Rubberized Fabric Sheet Making Machines have transformed the landscape of fabric production. They offer versatile and durable materials for a myriad of applications. The market continues to expand. Vatsn Tecnic emerges as a trusted partner. It provides cost-effective, high-quality solutions for businesses. They’re looking to invest in secondhand Rubberized Fabric Sheet Making Machines. Vatsn Tecnic commits to excellence. They are paving the way for a sustainable and innovative future in fabric manufacturing.

For more information Visit Here

Compression Molding

Compression Molding