Conveyor Belt Manufacturing Process in Maharashtra

Conveyor Belt Manufacturing Process in Maharashtra

Maharashtra is a prime industrial growth center in India. The state has a strong infrastructure for manufacturing industries, such as the manufacturing of conveyor belts. Having a regular conveyor belt manufacturing process in Maharashtra offers tremendous business opportunities.

In this blog, we will find out the benefits of having a well-known conveyor system manufacturing unit, government schemes for the industry, the best industrial areas to set up shop, and why Vatsn Tecnic is your best partner in this venture.

Benefits of a Reliable Conveyor Belt Production Process

An efficiently planned conveyor belt manufacturing process increases efficiency and profitability. Here’s why establishing a reliable conveyor system manufacturing unit is advantageous:

- Increased Production Efficiency: An efficient process means quicker production. This minimizes delays and maximizes output.

- Lower Operational Costs: Waste reduction in efficient manufacturing. This conserves raw materials and decreases the cost of production.

- Improved Product Quality: Uniform processes create robust and long-lasting conveyor belts. This helps establish trust among customers and the brand’s reputation.

- More Business Opportunities: Mining, logistics, and food processing sectors require quality conveyor belts. A stable production system guarantees steady demand.

- Rapid Expansion of Markets: A reliable manufacturing facility draws in more customers. This assists in rapidly expanding business networks.

Government Schemes for Trusted Conveyor System Manufacturing

The Indian government offers several schemes to support conveyor belt manufacturing businesses. Here are five key programs:

1. MSME Subsidy for Small Producers

- Financial assistance is offered by the Ministry of Micro, Small, and Medium Enterprises (MSME) to small conveyor belt manufacturers.

2. Make in India Initiative

- It promotes local manufacturing. Conveyor belt industries can avail themselves of tax concessions and investment incentives.

3. Industrial Cluster Development Scheme

- It assists companies in establishing themselves in industrial clusters. The clusters offer infrastructure and low setup expenses.

4. Credit Linked Capital Subsidy Scheme (CLCSS)

- This scheme provides subsidies for buying sophisticated machinery. Manufacturers of conveyor belts are able to modernize technology at a cheaper price.

5. Maharashtra State Industrial Policy

- The government of Maharashtra offers incentives such as the allocation of land, power subsidies, and tax-free status for new manufacturing facilities.

Best Industrial Areas for Setting Up a Conveyor Belt Production Unit

Maharashtra has several key industrial zones ideal for conveyor belt production. Here are the top five locations:

1. MIDC Pune

- Pune has good infrastructure and trained labor. It is most suited for sophisticated manufacturing facilities.

2. Chakan Industrial Area

- It is highly accessible by road and railway. It is suitable for heavy industrial manufacturing.

3. Aurangabad Industrial City (AURIC)

- AURIC provides state-of-the-art facilities and tax incentives. It is ideal for high-tech conveyor system production.

4. Nashik Industrial Zone

- Nashik boasts an emerging industrial base. It has easy access to raw materials and markets.

5. Taloja Industrial Estate

- It is situated near Mumbai. The region has robust logistics support. It facilitates business in distributing conveyor belts effectively.

How Conveyor Belts Are Made – Step-by-Step Guide

Making of high-quality conveyor belts is a multi-step operation. Let us list them out:

- Raw Material Selection: It begins with choosing robust rubber, fabric, or metal.

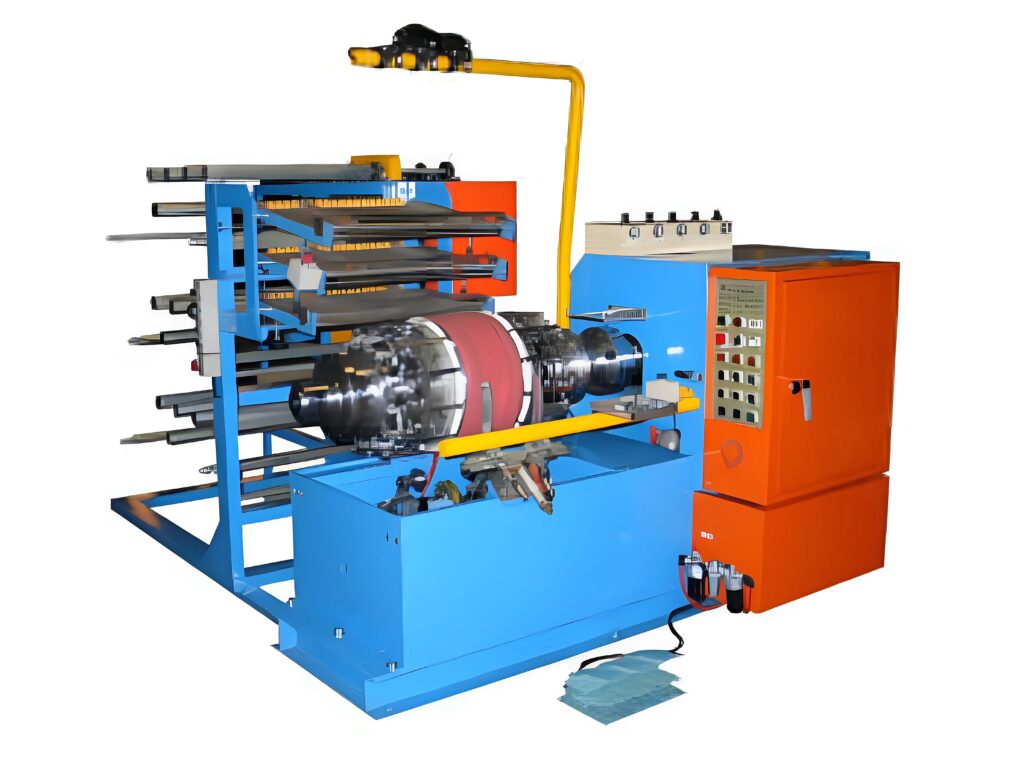

- Blending and Blending: The raw materials are blended together in order to design a flexible but strong belt form.

- Moulding and Moulding: The material is molded into a belting shape using exact machines.

- Vulcanization Procedure: Heat and pressure are utilized to make and toughen the belt.

- Quality Testing: The final products are put through intensive tests to make sure they meet industrial standards.

Why Choose Vatsn Tecnic for Conveyor Belt Manufacturing?

Vatsn Tecnic is a trusted name in rubber processing and conveyor belt production. Here’s why we are the best choice:

- Rubber Processing Expertise: We possess vast knowledge in manufacturing high-performance conveyor belts.

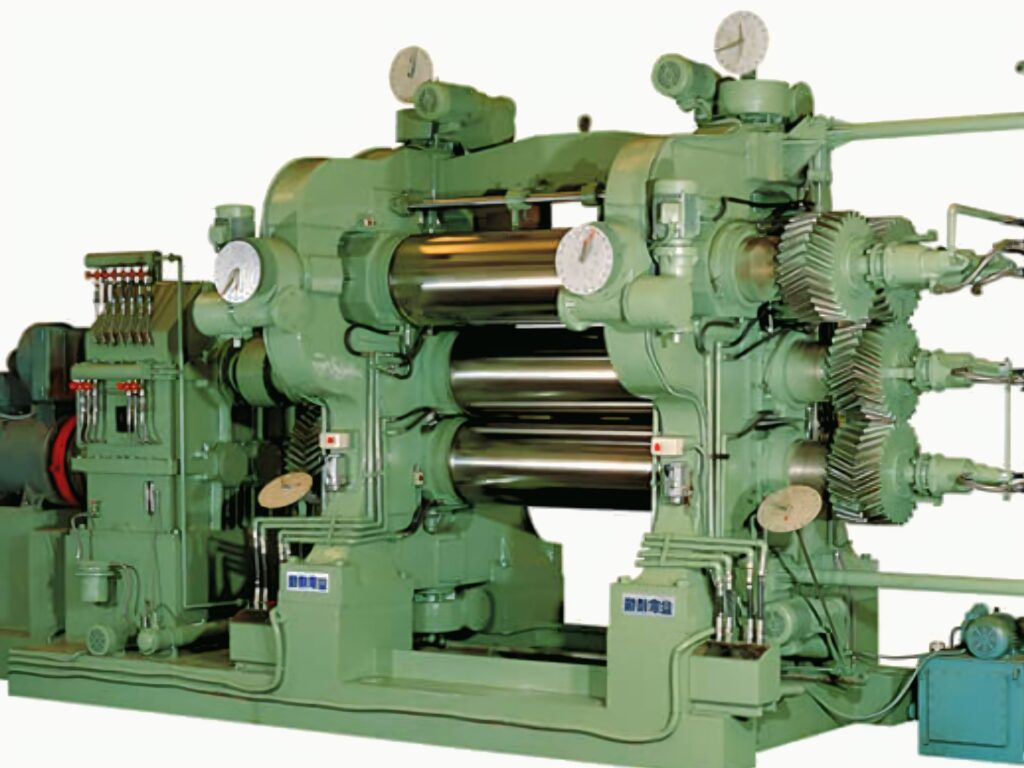

- Latest Technology and Machinery: Our manufacturing process includes the application of the most advanced machinery for precision and effectiveness.

- Quality Control at Each Step: We exercise very tight quality control to provide lasting and reliable conveyor belts.

- Affordable Solutions for All Sectors: We have competitive prices, and we are the company’s choice.

- Good After-Sales Support: We provide maintenance, servicing, and consultancy to ensure the business grows.

Conclusion

Establishing a conveyor belt production unit in Maharashtra is very lucrative. With government encouragement, robust industrial complexes, and enhanced demand, this sector has immense profit-making potential. If you are in search of a reliable conveyor belt manufacturer, Vatsn Tecnic is your ideal partner.

To know more, contact Vatsn Tecnic today!

For More Information Visit Here

Compression Molding

Compression Molding