Shop

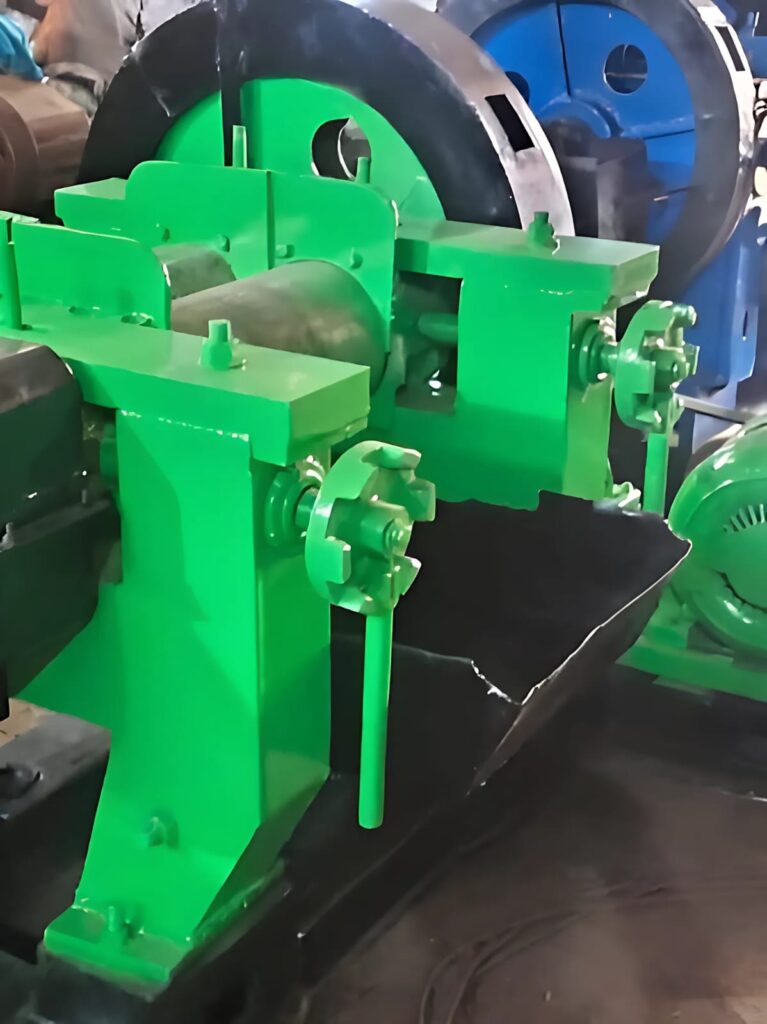

Buy | Sell Used Rubber Mixing Mill Sizes of 10 X 24 Motor 20 HP

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

Overall dimension(mm) | L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

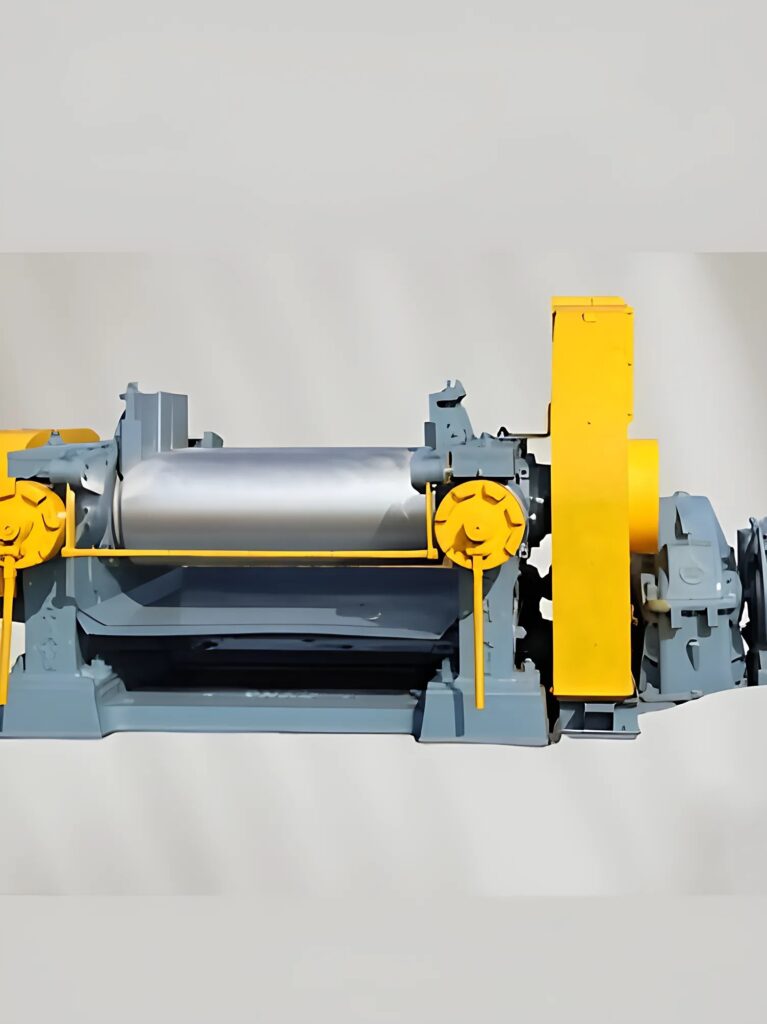

Buy | Sell Used Rubber Mixing Mill With Two Chilled Cast Iron Roll Motor 37kw

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

Overall dimension(mm) | L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

Buy | Sell Used Rubber Molding Hydraulic Press 400 X 400

| MODEL NO. | VAT-75 | VAT-100 | VAT-150 | VAT-200 | VAT-250 | VAT-300 | VAT-350 | VAT-400 | VAT-500 |

| PLATEN SIZE (MM) | 360x360 | 410x410 | 460x460 | 510x510 | 610x610 | 660x660 | 760x760 | 800x850 | 1000x1000 |

| MACHINE TONNAGE | 75 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 |

| RAM SIZE DIA (MM) | 220 MM | 250 MM | 300 MM | 350 MM | 400 MM | 450 MM | 500 MM | 550 MM | 600 MM |

| DAYLITE GAP | 500 MM | 500 MM | 500 MM | 400-500 MM | 400-500 MM | 400-500 MM | 400-500 MM | 500-800 MM | 500-900 MM |

| MAN MOTOR | 5 HP | 5 HP | 5 HP | 7.5 HP | 10 HP | 10 HP | 15 HP | 15 HP | 20 HP |

| MAIN RAM STROKE | 500 MM | 500 MM | 500 MM | 500 MM | 500 MM | 500 MM | 500 MM | 500 MM | 500 MM |

Buy | Sell Used Rubber Molding Hydraulic Press RAM SIZE FOR 300 TON

| MODEL NO. | VAT-75 | VAT-100 | VAT-150 | VAT-200 | VAT-250 | VAT-300 | VAT-350 | VAT-400 | VAT-500 |

| PLATEN SIZE (MM) | 360x360 | 410x410 | 460x460 | 510x510 | 610x610 | 660x660 | 760x760 | 800x850 | 1000x1000 |

| MACHINE TONNAGE | 75 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 |

| RAM SIZE DIA (MM) | 220 MM | 250 MM | 300 MM | 350 MM | 400 MM | 450 MM | 500 MM | 550 MM | 600 MM |

| DAYLITE GAP | 500 MM | 500 MM | 500 MM | 400-500 MM | 400-500 MM | 400-500 MM | 400-500 MM | 500-800 MM | 500-900 MM |

| MAN MOTOR | 5 HP | 5 HP | 5 HP | 7.5 HP | 10 HP | 10 HP | 15 HP | 15 HP | 20 HP |

| MAIN RAM STROKE | 500 MM | 500 MM | 500 MM | 500 MM | 500 MM | 500 MM | 500 MM | 500 MM | 500 MM |

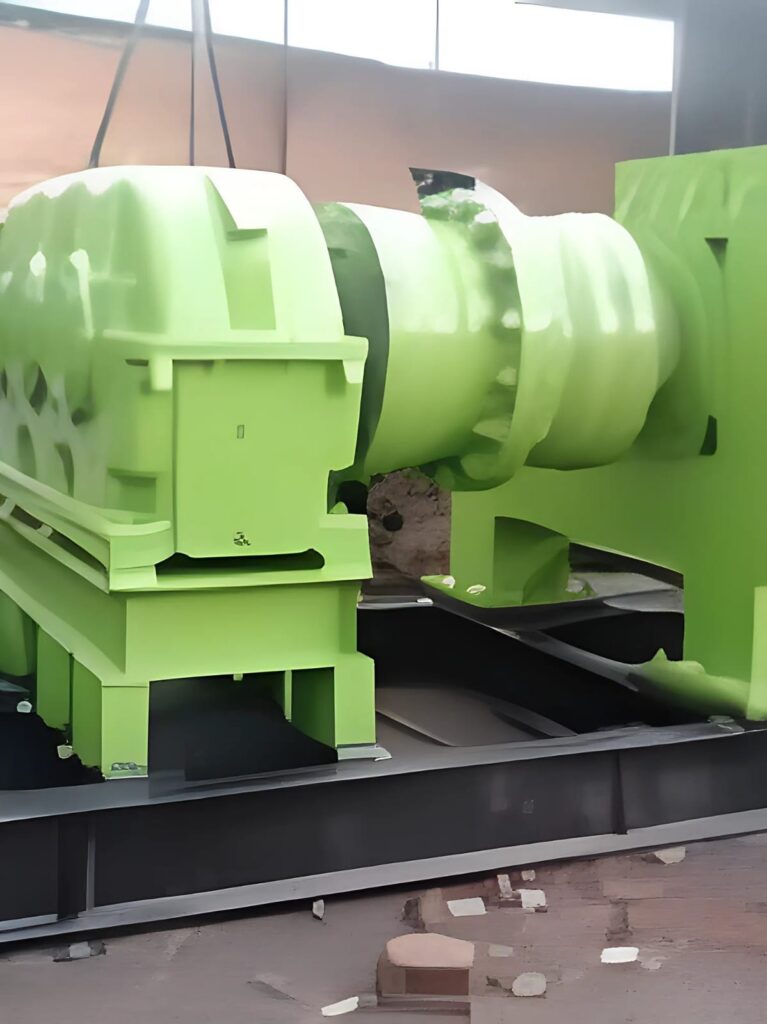

Buy | Sell Used Rubber Refiner Mill 450x510x1000 mm

| Working diameter of rolls(mm) | φ400front roller φ480rear roller | φ450front roller φ510rear roller | φ480front roller φ610rear roller |

| Roll casting process | centrifugal composite casting | centrifugal composite casting | centrifugal composite casting |

| Roll cooling mode | Around the borehole cooling | Around the borehole cooling | Around the borehole cooling |

| The surface of the roll material | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy |

| Working length of the roll(mm) | 650 | 800/1000 | 800/1000/1200 |

| After the roller line speed(m/min) | 32.94(optional) | 49/55.2/63.4(optional) | 57.5-75.1(optional) |

| Front and rear roller line speed ratio | 1.27-1.815(optional) | 1.38/1.82/2(optional) | 1.27-1.815(optional) |

| Production capacity(kg/h) | 300 | 360 | 500-800 |

| Motor power(kw) | 55 | 55 | 75/90 |

| Roller spacing adjustment range(mm) | 0.1-15 | 0.1-15 | 0.1-15 |

| Reducer | ZSY hard-tooth face gear | ZSY hard-tooth face gear | ZSY hard-tooth face gear |

| Bearing type | the double spherical roller bearing | the double spherical roller bearing | the double spherical roller bearing |

| Dimensions of LxWxH(mm) | 4750x2300x1835 | 4060x2200x1470 | 5070x2800x1978 |

| Quality(kg) | about 10500 | about 12800 | about 20000 |

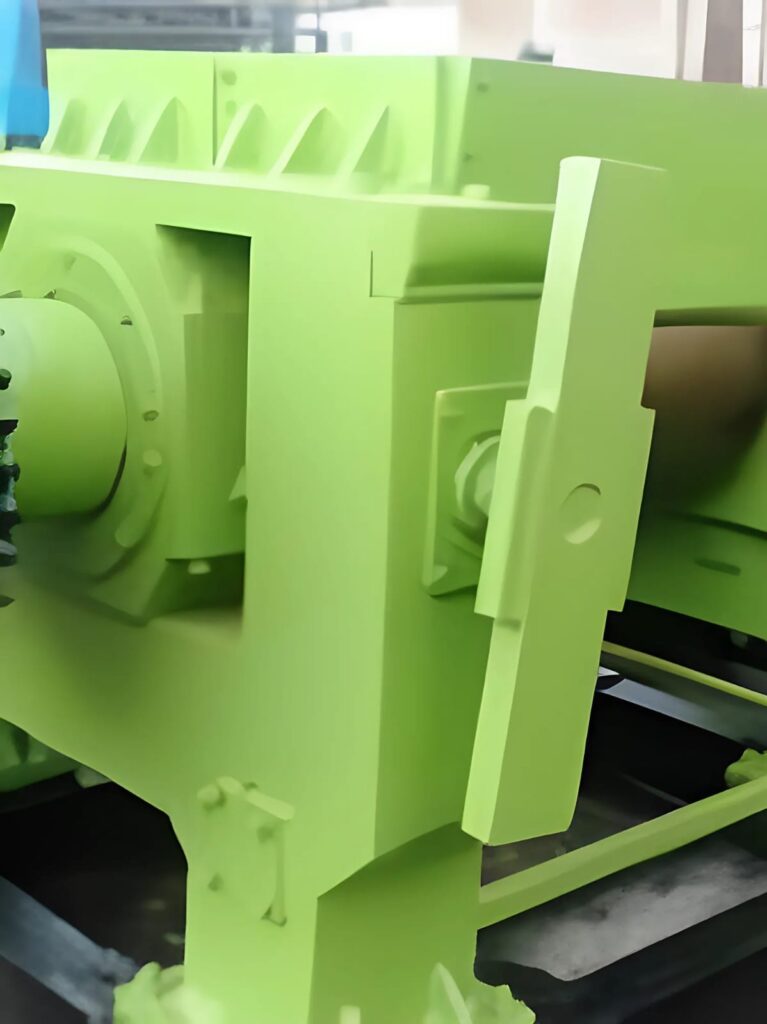

Buy | Sell Used Rubber Refiner Mill Size 21 X 24 X 36

| SIZE(inch.) | OD (mm) | SIZE(inch) | FRONT ROLL | REAR ROLL | CAPACITY (kg/hr) | OPERATION | DRIVE MOTOR (hp) | |

| VAT | 16"x12"x30" | 406.4/304.8 | 762 | 18 | 28 | 70-75 | Contenuous | 40 |

| VAT | 18"x14"x36" | 487.2/355.6 | 914.4 | 17 | 24 | 110-140 | Contenuous | 60/75 |

| VAT | 22"x18"x30" | 558.8/457.2 | 762 | 15 | 20 | 180-225 | Contenuous | 110/125 |

| VAT | 24"x20"x36" | 609.6/533.4 | 914.4 | 13.5 | 19 | 250-350 | Contenuous | 150 |

| VAT | 28"x24"x48" | 711.2/609.6 | 1219.2 | 11.5 | 16 | 375-500 | Contenuous | 200/250 |

Buy | Sell Used Rubber Refiner Mill XKP 450 X 510 X 1000 mm

| SIZE(inch.) | OD (mm) | SIZE(inch) | FRONT ROLL | REAR ROLL | CAPACITY (kg/hr) | OPERATION | DRIVE MOTOR (hp) | |

| VAT | 16"x12"x30" | 406.4/304.8 | 762 | 18 | 28 | 70-75 | Contenuous | 40 |

| VAT | 18"x14"x36" | 487.2/355.6 | 914.4 | 17 | 24 | 110-140 | Contenuous | 60/75 |

| VAT | 22"x18"x30" | 558.8/457.2 | 762 | 15 | 20 | 180-225 | Contenuous | 110/125 |

| VAT | 24"x20"x36" | 609.6/533.4 | 914.4 | 13.5 | 19 | 250-350 | Contenuous | 150 |

| VAT | 28"x24"x48" | 711.2/609.6 | 1219.2 | 11.5 | 16 | 375-500 | Contenuous | 200/250 |

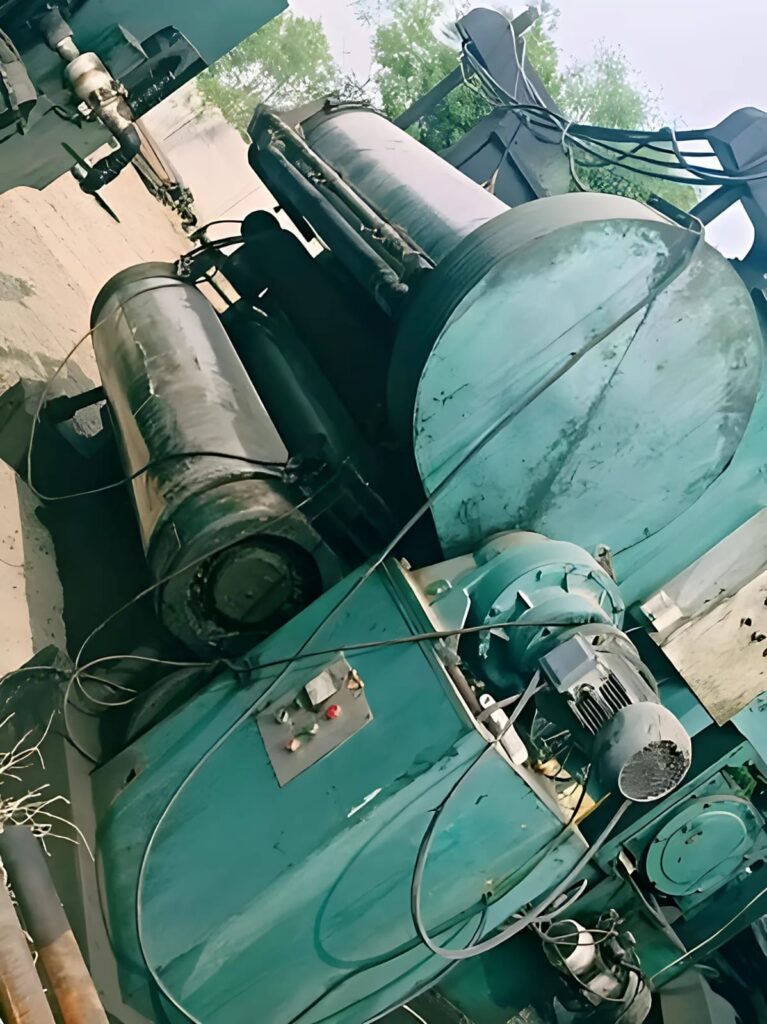

Buy | Sell Used Rubber Rotocure 1600 X 1200 mm

| DESCRIPTION | VAT-700-1700 | VAT-1000-1700 | VAT-1500-2000 | VAT-2000-2500 |

| Heating Drum Diameter | 700 | 1000 | 1500 | 2000 |

| Max Product. Width | 1600 | 1800-2000 | 1900 | 2000-2500 |

| Line Speed | 0.03-1.34 | 0.06-1.8 | 0.175-3.14 | 0.24-4.7 |

| Motor | 7.5.H.P | 10HP | 15HP | 20HP |

| Max Product Thickness | 0.5-25MM | 0.5-25 MM | 0.5-25 MM | 0.5-25 MM |

| Max Temp | 160-220o | 160-220o | 160-220o | 160-220o |

| Belt Make | SANDVIK | SANDVIK | SANDVIK | SANDVIK |

Buy | Sell Used Rubber Rotocure Curing Press 1850 X 750 mm

| Model | VAT-710X700 | VAT-710X1450 | VAT-1000X1600 | VAT-1250X1800 | VAT-1500X2400 | VAT-2000X3200 | VAT-2500X4200 | |

| Drum diameter (mm) | 710 | 710 | 1000 | 1250 | 1500 | 2000 | 2500 | |

| Max. Product width (mm) | 500 | 1150 | 1300 | 1500 | 2100 | 2900 | 3800 | |

| Product thickness (mm) | 0.5-5 | 0.5-5 | 1-8 | 1-8 | 1-10 | 1-10 | 1-10 | |

| Total pulling force of steel belt (kn) | 300 | 380 | 900 | 1100 | 1500 | 3300 | 5000 | |

| Drum liner speed (m/min) | 0.2-2 | 0.2-2 | 0.2-2 | 0.2-2 | 0.2-3 | 0.2-3 | 0.2-3 | |

| Curing pressure (map) | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | |

| Steam pressure (map) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |

| Main motor power (kw) | 2.2 | 3 | 3 | 3 | 5.5 | 7.5 | 11 | |

| Winding power (kW) | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 1.5 | 1.5 | |

Overall dimension (mm) | (L) | 2630 | 2630 | 3300 | 5790 | 6300 | 7200 | 8800 |

| (W) | 2440 | 3190 | 3300 | 4870 | 4900 | 7100 | 8400 | |

| (H) | 2730 | 2730 | 3500 | 4970 | 5100 | 5800 | 6200 | |

| Weight (t) | 15 | 20 | 25 | 28 | 32 | 100 | 200 | |

Buy | Sell Used Rubber Rotocure Machine 1200 mm X 1800 mm

cellspacing="0" cellpadding="0" data-sheets-root="1">idth="153" /><td colspan="2" rowspan="1" data-sheets-value="{"1":2,"2":"Drum diameter (mm)"}">Drum diameter (mm)<td data-sheets-value="{"1":3,"3":1000}">1000

| Model | a-sheets-value="{"1":2,"2":"VAT-710X700"}">VAT-710X700 | VAT-710X1450 | VAT-1000X1600 | VAT-1250X1800 | VAT-1500X2400 | -value="{"1":2,"2":"VAT-2000X3200"}">VAT-2000X3200 | ts-value="{"1":2,"2":"VAT-2500X4200"}">VAT-2500X4200 | |

| 710 | 710 | 1250 | 1500 | 2000 | 2500 | |||

| Max. Product width (mm) | 500 | 1150 | 1300 | 1500 | 2100 | 2900 | 3800 | |

| Product thickness (mm) | 0.5-5 | 0.5-5 | 1-8 | 1-8 | value="{"1":3,"3":45301}" data-sheets-numberformat="{"1":5,"2":"m-d","3":1}">1-10 | 1-10 | 1-10 | |

| Total pulling force of steel belt (kn) | 300 | 380 | 900 | 1100 | 1500 | 3300 | 5000 | |

| Drum liner speed (m/min) | 0.2-2 | 0.2-2 | 0.2-2 | 0.2-2 | 0.2-3 | 0.2-3 | 0.2-3 | |

| Curing pressure (mpa) | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | |

| Steam pressure (mpa) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |

| Main motor power (kw) | 2.2 | 3 | 3 | 3 | 5.5 | 7.5 | 11 | |

| Winding power (kw) | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 1.5 | 1.5 | |

Overall dimension (mm) | (L) | 2630 | 2630 | 3300 | 5790 | 6300 | 7200 | 8800 |

| (W) | 2440 | 3190 | 3300 | 4870 | 4900 | 7100 | 8400 | |

| (H) | 2730 | 2730 | 3500 | 4970 | 5100 | 5800 | 6200 | |

| Weight (t) | 15 | 20 | 25 | 28 | 32 | 100 | 200 | |

Buy | Sell Used Rubber Rotocure Machine 700 X 1600

| Model | VAT-710X700 | VAT-710X1450 | VAT-1000X1600 | VAT-1250X1800 | VAT-1500X2400 | VAT-2000X3200 | VAT-2500X4200 | |

| Drum diameter (mm) | 710 | 710 | 1000 | 1250 | 1500 | 2000 | 2500 | |

| Max. Product width (mm) | 500 | 1150 | 1300 | 1500 | 2100 | 2900 | 3800 | |

| Product thickness (mm) | 0.5-5 | 0.5-5 | 1-8 | 1-8 | 1-10 | 1-10 | 1-10 | |

| Total pulling force of steel belt (kn) | 300 | 380 | 900 | 1100 | 1500 | 3300 | 5000 | |

| Drum liner speed (m/min) | 0.2-2 | 0.2-2 | 0.2-2 | 0.2-2 | 0.2-3 | 0.2-3 | 0.2-3 | |

| Curing pressure (map) | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | 0.5-3.8 | |

| Steam pressure (map) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |

| Main motor power (kw) | 2.2 | 3 | 3 | 3 | 5.5 | 7.5 | 11 | |

| Winding power (kW) | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 1.5 | 1.5 | |

Overall dimension (mm) | (L) | 2630 | 2630 | 3300 | 5790 | 6300 | 7200 | 8800 |

| (W) | 2440 | 3190 | 3300 | 4870 | 4900 | 7100 | 8400 | |

| (H) | 2730 | 2730 | 3500 | 4970 | 5100 | 5800 | 6200 | |

| Weight (t) | 15 | 20 | 25 | 28 | 32 | 100 | 200 | |

Compression Molding

Compression Molding