Introducing the cutting-edge Rubber Mixing Mill Machine with Stock Blender – your ultimate solution for efficient rubber processing! Looking to boost your production capabilities? This machine boosts your productivity. Whether you’re in rubber manufacturing or not.

Key Features-

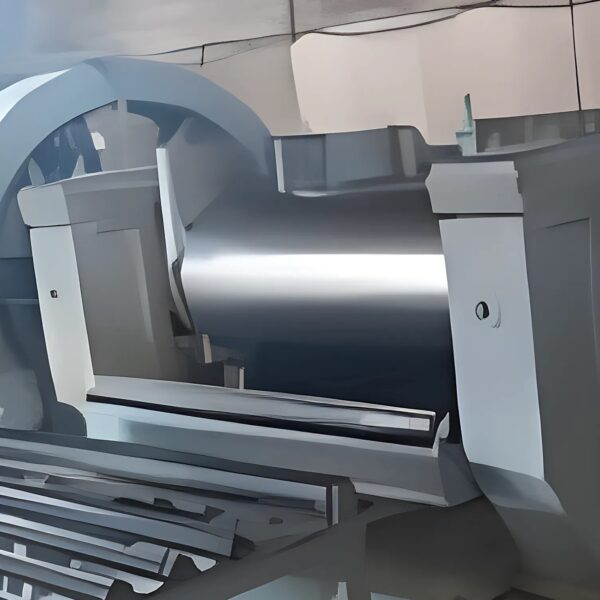

- Precision Mixing: Our Rubber Mixing Mill Machine ensures uniform and thorough mixing of rubber compounds. The precision-engineered rollers facilitate optimal dispersion of ingredients, guaranteeing consistent quality in every batch.

- Advanced Stock Blender: Take control of your mixing process with the integrated Stock Blender. This feature allows for real-time adjustments, ensuring homogeneity and reducing the chances of material inconsistencies. Say goodbye to uneven batches and hello to superior rubber compounds.

- High-Quality Construction: Crafted from durable materials and engineered with precision, this mixing mill machine is built to withstand the demands of rigorous industrial use. The robust construction ensures longevity and minimal maintenance requirements, contributing to a reliable and cost-effective solution.

- User-Friendly Interface: The machine boasts an intuitive interface that simplifies operation. With user-friendly controls and a clear display, operators can easily monitor and adjust settings, streamlining the mixing process for maximum efficiency.

- Versatile Applications: From tire manufacturing to rubber sheet production, this machine adapts to a variety of applications. Its versatility makes it an invaluable asset for businesses involved in rubber processing across different industries.

- Energy-Efficient Design: Embrace sustainability without compromising performance. Our Rubber Mixing Mill Machine is designed with energy efficiency in mind, minimizing power consumption while maximizing output. This eco-friendly approach aligns with modern manufacturing standards.

- Safety First: Prioritize the safety of your operators with built-in safety features. Emergency stops, protective guards, and user-friendly controls contribute to a secure working environment.

- Easy Maintenance: Minimize downtime with easy-to-access components and straightforward maintenance procedures. Regular upkeep is a breeze, allowing you to focus on production without prolonged interruptions.

For more information Visit Here

Compression Molding

Compression Molding